Choosing the Right Sensor for Harsh Environments in Fuel Cell Technology

Electric vehicles (EVs) have recently gained a huge amount of attention in the evolving transportation landscape.

According to the latest statistics, an estimated 14 million EVs are projected to be sold in 2023, reflecting a 35% year-on-year increase.1 Fuel cell EVs have also attracted attention from major players in the auto industry, including Toyota, Honda, and BMW.2,3,4

However, manufacturing fuel cell EVs poses significant challenges. Their reputation for being clean and eco-friendly, a remedy for our polluted past, is hard-earned.

This article will elaborate on the various internal components of a fuel cell EV, which must maintain different pressures to ensure optimal performance and safety. The pressure sensors, situated amidst these components, play a crucial role in monitoring the system.

Understanding Hydrogen Fuel Cells

Hydrogen fuel cells represent pioneering technology in sustainable energy. These cells harness the power of hydrogen, combining it with oxygen from the air to produce electricity, with only water vapor as the emission.

Currently, hydrogen’s use as an energy carrier is mainly for road vehicles. As of June 2021, over 40,000 fuel cell EVs were operational globally, with nearly 90% concentrated in four countries: Japan, Korea, China, and the United States.5

The utilization of hydrogen fuel cells is expected to grow, with CEM H2I leading the efforts to promote fuel cell technologies worldwide through collaboration with governments and partners.6

The Vital Role of Decompressing Hydrogen

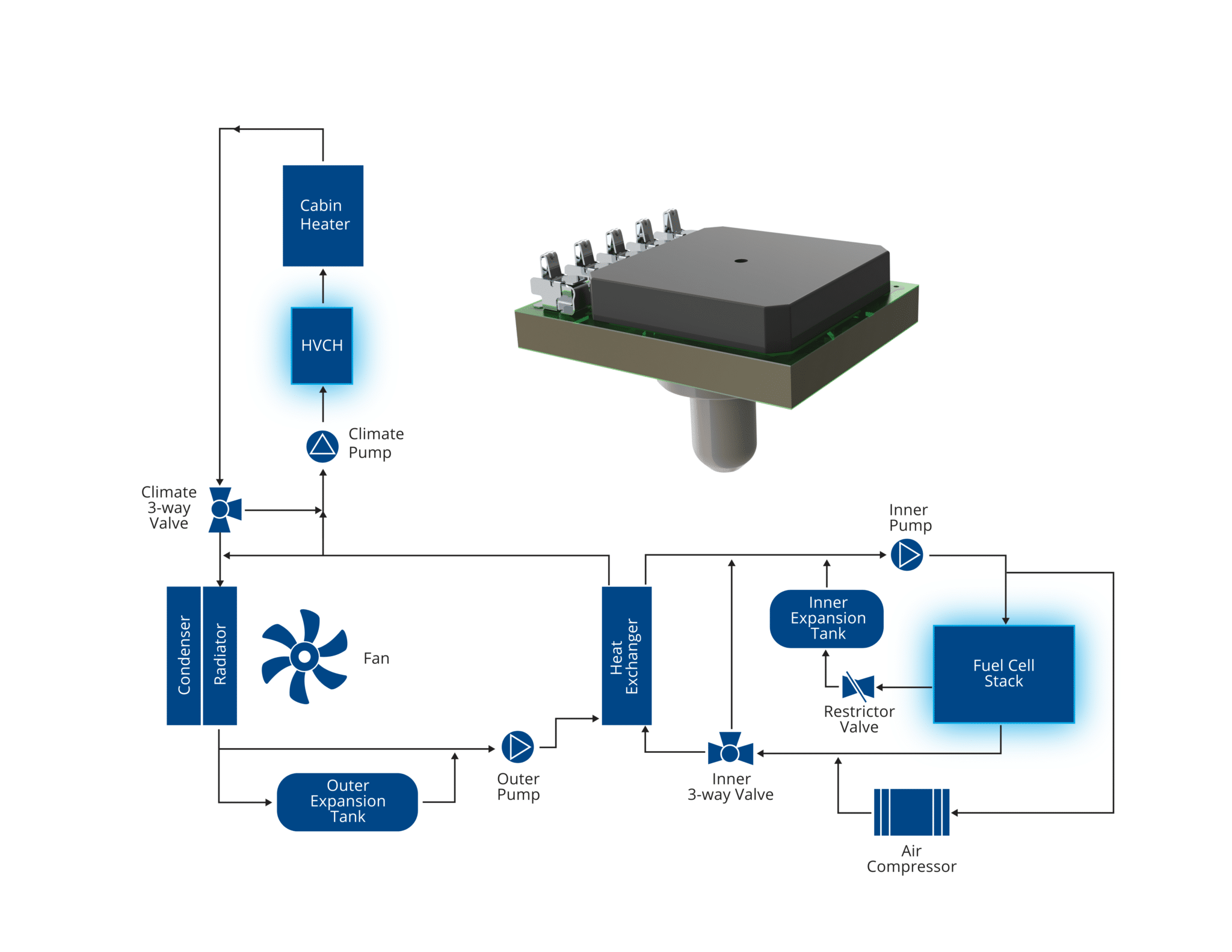

In a typical hydrogen fuel cell EV, hydrogen is stored in a high-pressure container. However, because the fuel cell stack operates optimally at significantly lower pressure, a decompression procedure is necessary to bridge the gap between the high-pressure hydrogen tank and the fuel cell stack.

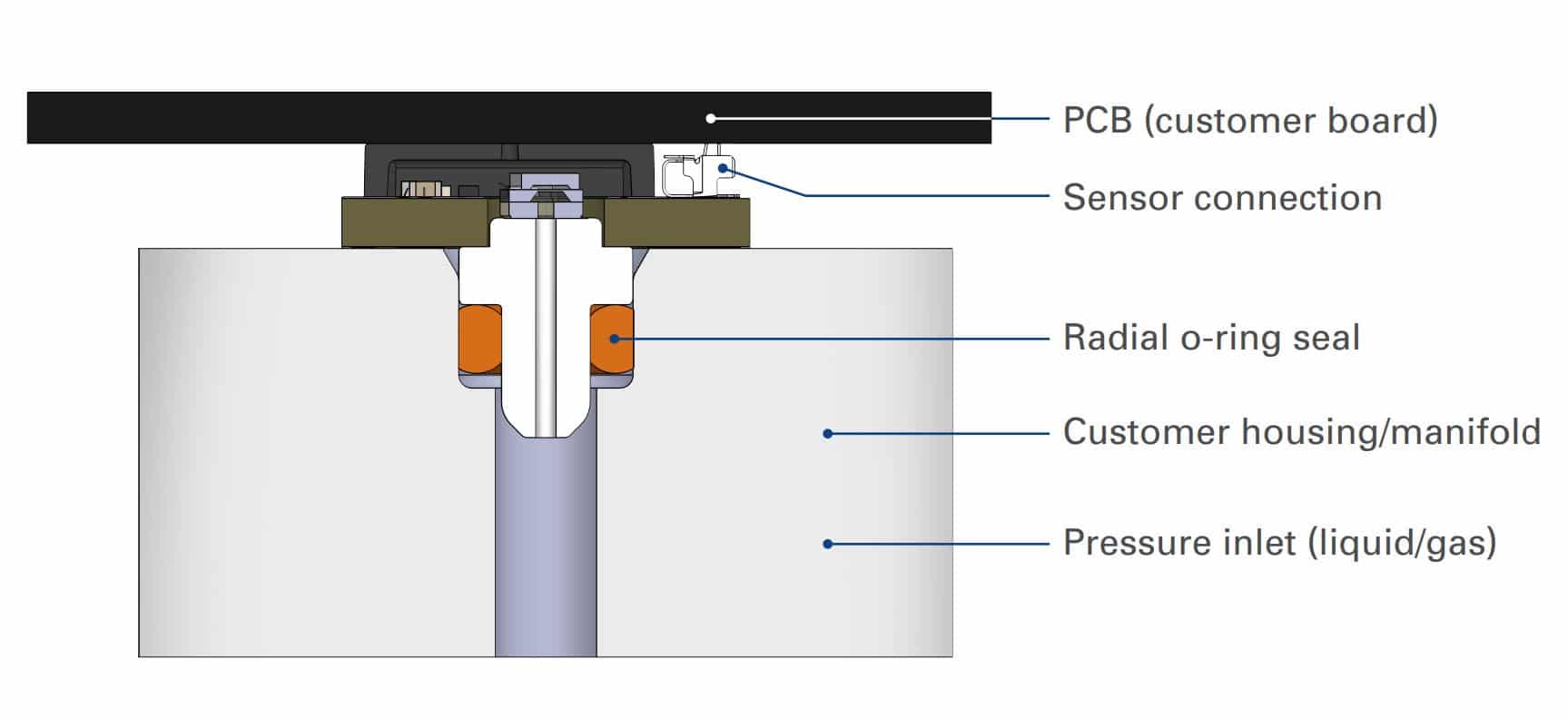

The decompression of hydrogen is crucial for the fuel cell to function effectively.7 Hydrogen, being the smallest particle, does not affect the absolute TRVC function, making radial sealing critical in design due to TRVC and plug geometry.

Significance of Heat Management Systems in EVs

Heat management, such as efficient cooling systems, plays a key role in the performance and lifespan of fuel cells.8

Making sure heat dissipates effectively is essential to keep critical parts like the battery and electronic systems within the required temperature limits. For batteries, this often means using a dedicated battery thermal management system (BTMS).

Keeping the right pressure in cooling systems specific to each EV is vital to prevent coolant leaks and potential damage to components.9

Importance of Pressure Sensors in Fuel Cell Technology

Precise pressure measurement is essential during energy generation and heat management. Accurate pressure sensors are necessary to monitor gas flow in pipelines and maintain proper coolant levels in the cooling system.

Sensors face challenges in harsh environments with corrosive substances, temperature changes, and high-pressure fluctuations. Thus, pressure sensors deployed in these settings must be designed to endure harsh conditions.

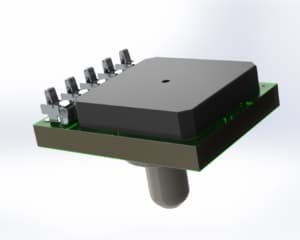

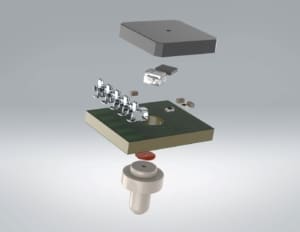

Introducing Merit Sensor’s TRVF-Series of Pressure Sensors

Merit Sensor, a top player in piezoresistive pressure sensors, crafted the TRVF-Series to meet industry needs. These sensors seamlessly integrate into fuel cell systems’ hydrogen supply and coolant circuits, ensuring top-notch stability.

Capable of handling temperatures from -40 °C to 150 °C, the TRVF-Series boasts exceptional durability thanks to its trio of materials – silicon, glass, and ceramic. These sensors are built to endure the harsh conditions within fuel cell environments.

The aforementioned materials also guarantee compatibility with various liquids, vapors, and gases, from fuel to water, ensuring longevity and reliability in challenging operational settings.

Covering a pressure range of 2–15 bar, the TRVF-Series offers precise measurements and accurate analog voltage output, enabling effective monitoring of gas and liquid pressures for optimized energy generation and improved heat management processes.10

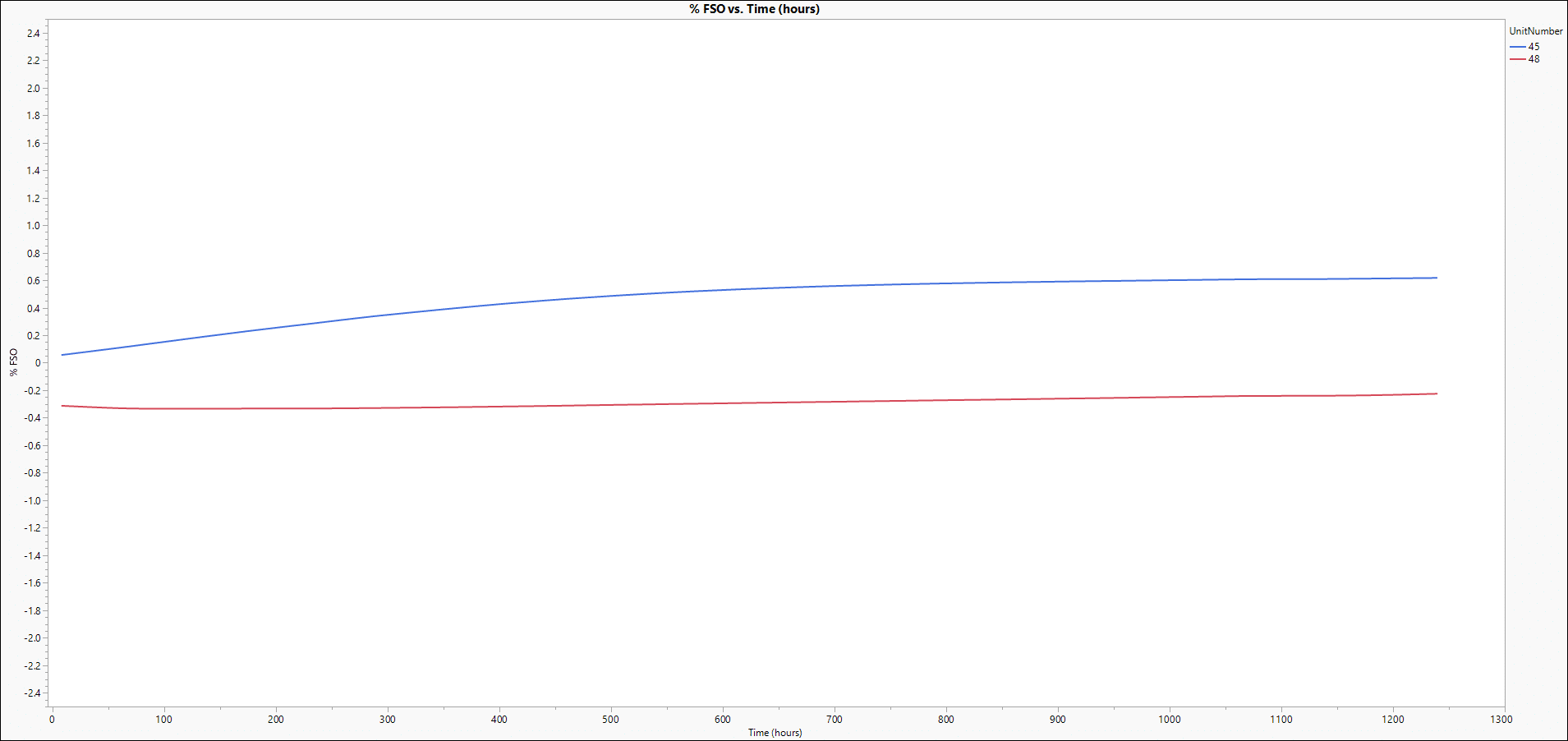

The graph illustrates the stability results of the TRVF Series measured at 150 °C for 1300 hours.

Enhanced Reliability in Coolant Circuit Measurements

TRVF sensors have been designed to collect pressure measurements from its posterior surface. This is achieved by hermetically sealing the MEMS silicon die on top of a ceramic port, ensuring that the media only touches the desired wetted materials.

This functionality allows the sensor to consistently provide dependable readings within the coolant system, ensuring efficient coolant control and contributing to the overall effectiveness and performance of the fuel cell system.10

Measured Under Pressure: Serving Fuel Cell Technology with the TRVF-Series

The introduction of Merit Sensor’s TRVF-Series marks a significant advancement in fuel cell technology, addressing the crucial need for durable and accurate sensors capable of enduring the tough conditions within fuel cell systems.

With its sturdy build and dependable performance, the TRVF-Series is positioned to have a significant impact on driving the advancement of sustainable transportation and energy solutions, establishing a new standard of excellence in sensing technology for harsh fuel cell environments.

References and Further Reading

- IEA. Global EV Outlook 2023: Executive Summary. Available at: https://www.iea.org/reports/global-ev-outlook-2023/executive-summary (Accessed on 31 August 2023).

- Toyota. Toyota Launches the New Mirai. Available at: https://global.toyota/en/newsroom/toyota/33558148.html (Accessed on 31 August 2023).

- Honda. Honda To Begin U.S. Production of Fuel Cell Electric Vehicles in 2024. Available at: https://hondanews.com/en-US/releases/honda-to-begin-us-production-of-fuel cell-electric-vehicles-in-2024 (Accessed on 31 August 2023).

- BMW. BMW Group brings hydrogen cars to the road: BMW iX5 Hydrogen pilot fleet launches. Available at: https://www.press.bmwgroup.com/global/article/detail/T0408839EN/bmw-group-brings-hydrogen-cars-to-the-road:-bmw-ix5-hydrogen-pilot-fleet-launches?language=en (Accessed on 31 August 2023).

- IRENA. Hydrogen: Overview. Available at: https://www.irena.org/Energy-Transition/Technology/Hydrogen (Accessed on 31 August 2023).

- IEA. CEM Hydrogen Initiative. Available at: https://www.iea.org/programmes/cem-hydrogen-initiative (Accessed on 31 August 2023).

- Qian, JY., et al. (2019) Hydrogen decompression analysis by multi-stage Tesla valves for hydrogen fuel cell. International Journal of Hydrogen Energy. doi.org/10.1016/j.ijhydene.2019.03.235.

- Ahn, J-W., et al. (2008) Coolant controls of a PEM fuel cell system. Journal of Power Sources. doi.org/10.1016/j.jpowsour.2007.12.066

- Vehicle Service Pros. Hybrid and EV cooling system service. Available at: https://www.vehicleservicepros.com/service-repair/battery-and-electrical/article/21197978/hybrid-and-ev-cooling-system-service (Accessed on 31 August 2023).

- Merit Sensor. TRVF-Series: Available Now! Available at: https://meritsensor.com/products/trvf-series/ (Accessed on 31 August 2023).

View this article on AzoSensors.com