TR Series Pressure Sensor Based Inches of Water Pressure Switch

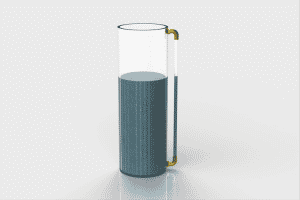

In many situations there is a need to know the level of a liquid in a tank or the pressure inside of an air duct. Both of these cases are quite low pressure and can be difficult to measure. This can be accomplished in several ways. The simplest is a sight glass or sight tube, as shown below. This works on the premise that liquid in the tank will force liquid up the sight tube to the same level as what is in the tank, or the air pressure being measured will raise the liquid level equal to the pressure applied. A monometer is a commonly used device for measuring low air pressure/vacuum. This is particularly useful in a tank that is not transparent, or at least translucent. In the case of an air duct, there is nothing visible so an external device of some sort is required. Although this is a simple approach, it is not particularly convenient because it needs to be located at the tank or close to the duct being measured. This is not useful if remote monitoring is required, and even less useful if any sort of feedback is desired as it is completely manual.

If remote monitoring of the level is required, there are several more options. A common example is a float type resistive (potentiometer) sensor, as typically found in an automotive fuel tank level sending unit. These sensors work well, but have some drawbacks.

- Located in the tank

- Displace some volume in the tank

- Moving parts

Tank with float type level sensor

Depending on the media being measured, and the design of the components, this type of sensor can fall victim to malfunctions caused be the media itself. A common issue is the float absorbing the media it is submerged in, which would result in an artificially low level reading because the float will lose some buoyancy.

In order to provide a reliable level sensor, one with no moving parts is very desirable. To accomplish this, a sensor such as Merit Sensor Systems’ TR series could be utilized. The TR series pressure sensor is a piezoresistive MEMS pressure sensing element paired with an ASIC on a ceramic substrate. The sensor is available in many pressure ranges, gage or absolute pressure measurement as well as custom calibration and output.

In order to realize the most accurate level reading possible a gage part should be used. This is preferred because the atmospheric pressure acting on the fluid in the tank will also act on the reference side of the MEMS pressure sensor providing the most accurate reading even while atmospheric pressure changes. In the case of a differential air pressure measurement, the reference can be atmospheric or another space. Some examples of this are:

- Building duct static pressure measurement (atmospheric to pressurized duct (inches of water typically))

- Building high duct static pressure (similar to regular duct static, but typically wired into the fan controller to turn off the fans if the pressure exceeds a safe level for the building and air supply system (inches of water typically))

- Building air filter status (differential pressure across filter – larger differential as filters become blocked (inches of water typically))

- Building space to space pressure (differential pressure between two spaces to ensure air flow is going in the right direction – common in clean rooms (tenths of an inch of water typically))

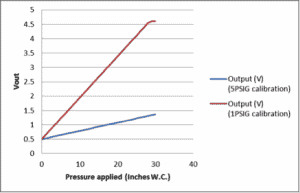

Measuring levels, for media such as water or air, is difficult as one inch of water measured at 39°F is a mere ≈ 0.0360911906567 PSI. Merit’s TR series is offered in a high sensitivity (low pressure) configuration that, when calibrated to 5 PSIG, could resolve to 1” of water. It is possible to achieve better resolution with a different calibration and/or custom MEMS device with higher sensitivity.

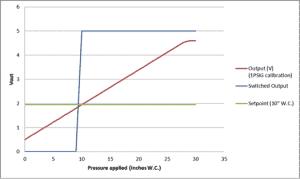

Below is a plot showing the difference between a 5PSIG calibration and a 1 PSIG calibration. There is a significant difference in the output of the sensor, giving much better resolution.

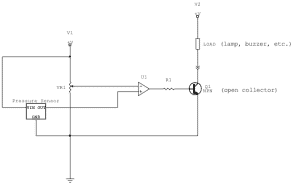

Once the sensor with an acceptable resolution has been selected there are options for the sensor interface. The TR series sensor provides a linear voltage output of 0.5 to 4.5V from minimum pressure to maximum pressure, and it is temperature compensated. This voltage can be monitored by a system controller or simply connected to a circuit, such as the one below, which would provide a variable level threshold via VR1. This could be used as a low level indicator/alarm or a overfill indicator alarm, depending on the configuration of the circuit.

Below is an example of the operation of the above circuit. This is an ideal, theoretical, example. With VR1 set to a calculated voltage for the desired level (10” W.C. in this case, or ~1.94V), the output of U1 will go high when the sensor voltage reaches the setpoint of VR1.

Whether a variable signal is desired, or a simple ON/OFF will suffice, a low pressure TR series sensor can be used. Several of the applications discussed here are currently handled by other sensor technologies, but could be handled very well by a properly designed, and implemented, MEMS based sensor.