Implementing Pressure Sensors into HVAC Systems

HVAC systems are vital when it comes to ensuring indoor air quality, health, and inhabitant comfort management.1 HVAC systems also have a central role in enhancing a building’s energy efficiency, as HVAC systems represent almost 50 % of the total energy consumption of buildings in the US and 20 % of all total energy consumption.2

Global temperatures and weather are likely to force an increased reliance on HVAC systems worldwide, meaning increased energy consumption which places utmost importance on finding ways to improve the efficiency of HVAC systems.3

One of the ways to achieve this is by using smart management systems for HVAC to do things like switch off unnecessary heating or ventilation in low or zero-occupancy buildings to ensure that no energy is wasted.4

The use of sensors lies at the core of smart HVAC systems. Sensors facilitate ‘machine vision’ for an automated system, delivering the information required to make intelligent decisions predicated on current demand and specified performance.

Sensors can also be incorporated into HVAC systems to enhance climate control and help send alerts when necessary maintenance to avoid needless work, which may also prevent system downtime.

Pressure Sensors in HVAC

Merit Sensor Systems is a global leader in the design and development of high-performance pressure sensors. Pressure sensors are one of the most important components in HVAC system technology for monitoring system performance, reviewing compressor conditions, and monitoring ducts to test the airflow through the ventilation systems.

Merit Sensor Systems has the services that help clients find the appropriate pressure sensors to make HVAC systems safer, more reliable, and cheaper to run.

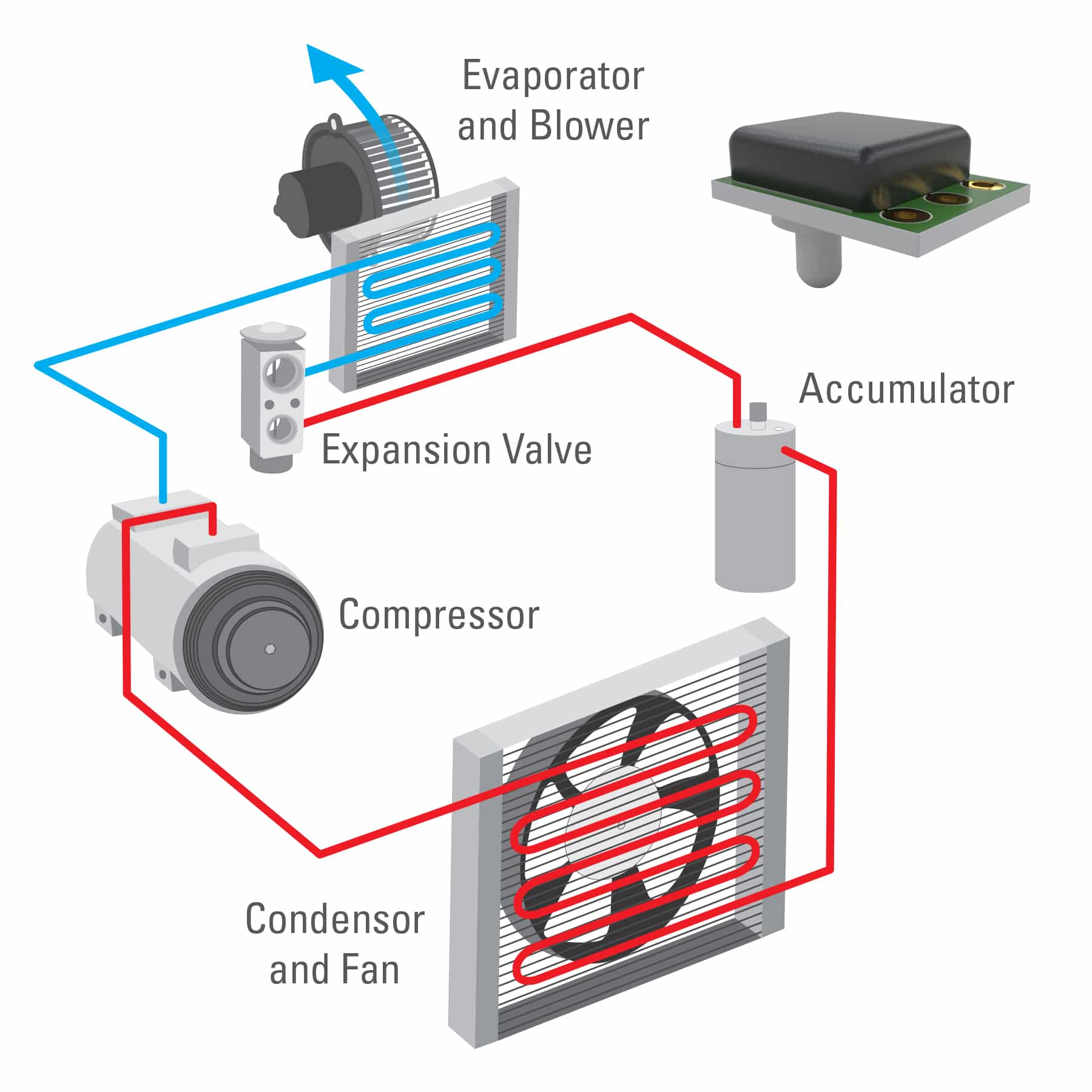

HVAC systems are made of several components as a single system will need to have the capacity of cooling, warming, and providing air transport around the system and ventilation.

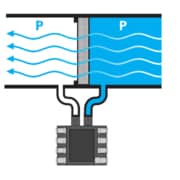

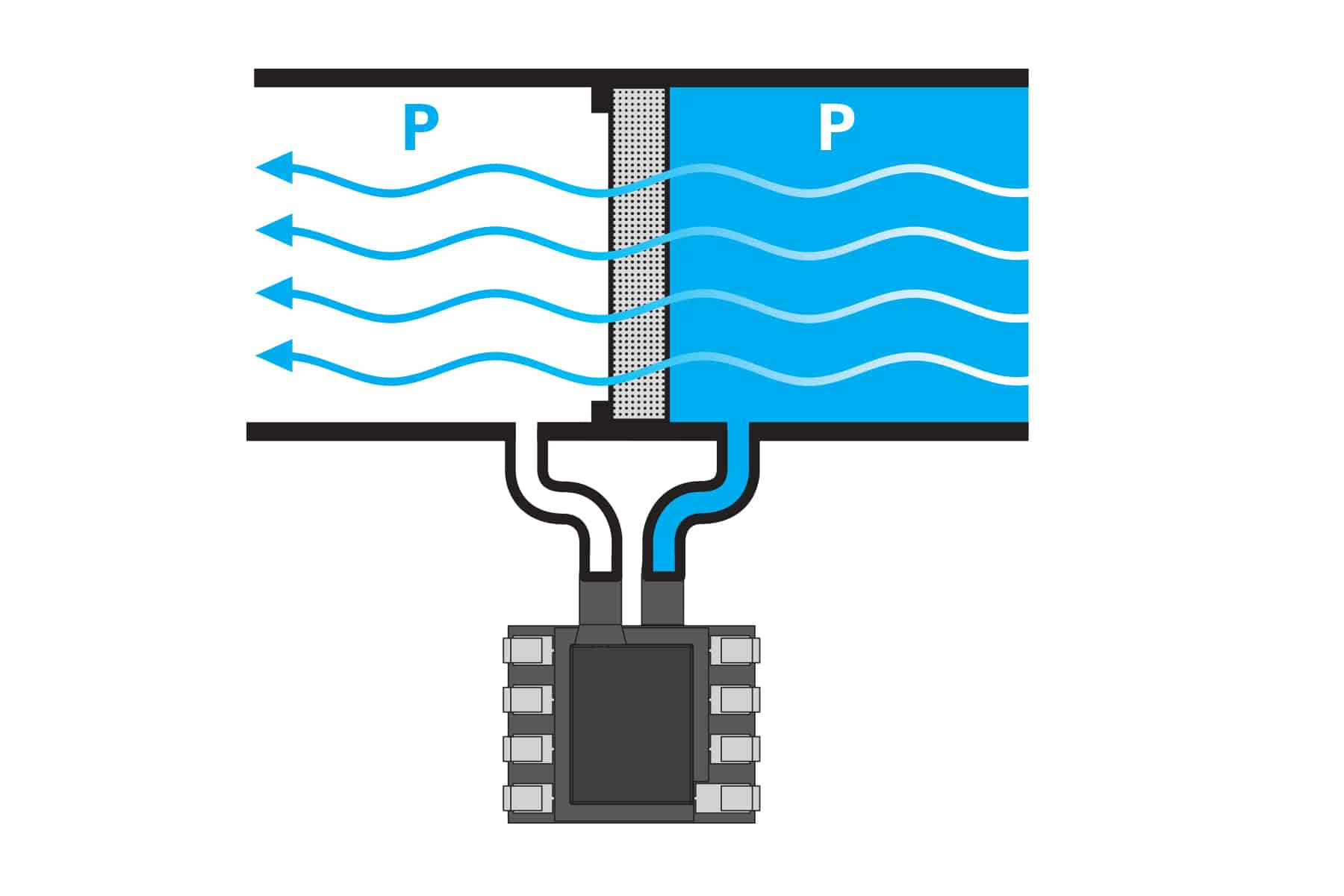

Continuous real-time pressure monitoring is suitable for checking if rooms or filters have pressure drops across them in order to check occupancy and performance. HVAC pressure sensors can also be installed to preserve pressure levels in key airways or those that necessitate positive pressures for safety reasons, including hospital laboratories.

LP Pressure Sensor

Compression

Conventional HVAC units typically contain a compressor that compresses a refrigerant vapor until it is transformed into a hot gas.

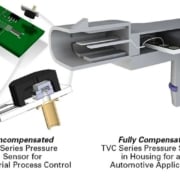

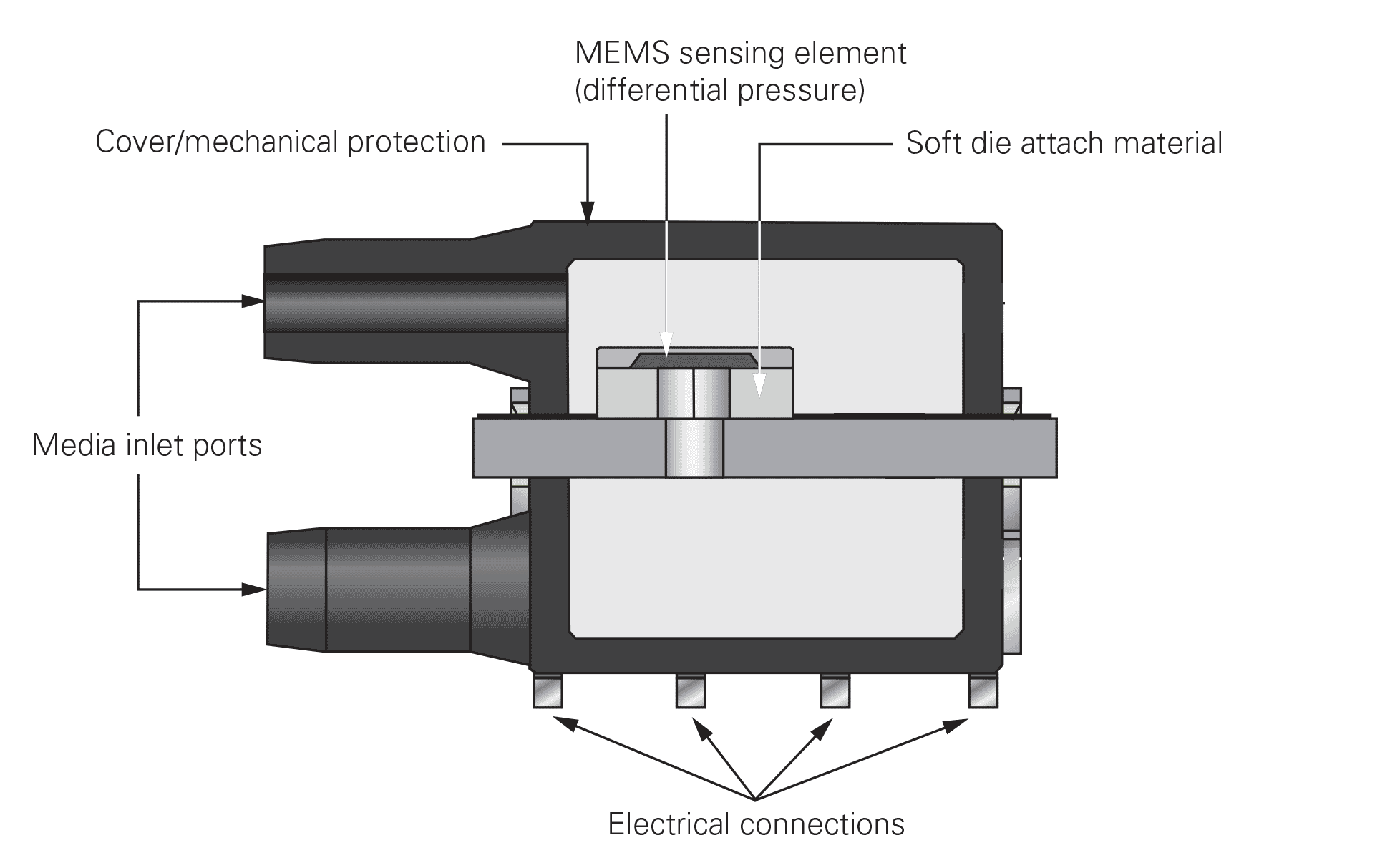

Pressure monitoring is crucial to check for leaks in this refrigerant application and the compressor performance, which is made possible with the TVC Series. Once the hot air is produced, it is cooled with ambient air that is subsequently heated by the transfer.

The gaseous refrigerant is pumped towards an evaporator as it cools, where it flows through a restrictor device to reduce the pressure of the refrigerant and evaporate it, cooling the air for recirculation.

There are various compressor designs, but the majority utilize the compression, evaporation, and cooling cycle to lower the air temperature.

TVC Pressure Sensor

Choosing Pressure Sensors

There are a number of different applications and a significant demand for pressure sensors in HVAC systems, but to be useful, pressure sensors need to have specific performance levels.

Some of the pressure changes in HVAC, including pressure drops across filters as a result of slight clogging, may be very small. Therefore, the pressure sensor needs to have a good limit of detection.

Small pressure changes and small overall pressures can also be observed in ventilation systems that require extremely sensitive pressure sensors. As smart HVAC systems are typically used to reduce energy consumption and waste, the pressure sensors that are installed in the system need to be completely reliable.

Errant and erroneous readings could lead to poor performance in the HVAC system or even damage components if maintenance warnings are not offered at the appropriate times.

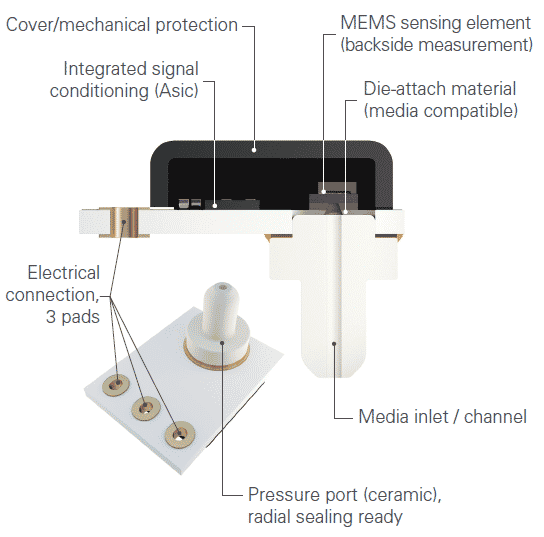

The extremely compact LP Series pressure sensor is also part of Merit Sensor Systems’ portfolio and helps address all of these issues.

The LP Series pressure sensor has a low footprint and can be easily integrated into a circuit board design without resulting in extra bulk or weight to the finished product. The small footprint makes integration into nearly any application possible without the need for majorly redesigning components.

LP Pressure Sensor

LP and TVC Series Pressure Sensors

For HVAC applications, the LP Series pressure sensor has a detection capacity down to just 250 Pa with a resolution of more than 0.01 Pa. Initially designed with a sensitivity for the measurement of differential or gauge pressures, this pressure sensor requires just a 3.3- to 3.5 V supply to start supplying accurate and meaningful data.

The LP series pressure sensor contains two connectable (with tubing) pressure points. The sensor can then be connected via I2C or analog output for data monitoring in real-time as well as integration into smart building management systems.

The TVC Series is ideal for measuring refrigerant gas at higher pressures. It was developed to create a stable output, even at temperatures between –40 to 150 °C. The TVC is tasked with monitoring HVAC systems, water levels, water pressure and processes. It can also be used for air-conditioning and other refrigerant systems.

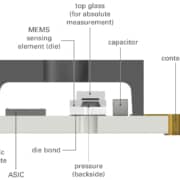

Inside the TVC Pressure Sensor

Inside the LP Pressure Sensor

Contact Merit Sensor Systems today to discover more and discover how the LP and TVC Series can revolutionize the efficiency of HVAC systems, with the sensitivity to determine exactly when the next maintenance cycle is due.

References and Further Reading

- Bearg, D. W. (2019). Indoor air quality and HVAC systems. Routledge. https://doi.org/10.1201/9780203751152

- Perez-Lombard, L., Ortiz, J., & Pout, C. (2008). A review on buildings energy consumption information ´. Energy and Buildings, 40, 394–398. https://doi.org/10.1016/j.enbuild.2007.03.007

- Wang, H., & Chen, Q. (2020). Impact of climate change heating and cooling energy use in buildings in the United States. Energy & Buildings, 82(2014), 428–436. https://doi.org/10.1016/j.enbuild.2014.07.034

- Wang, H., & Chen, Q. (2020). Impact of climate change heating and cooling energy use in buildings in the United States. Energy & Buildings, 82(2014), 428–436. https://doi.org/10.1016/j.enbuild.2014.07.034

For more information, visit this article on AZOSensors.com