Inside a Car – Oil Pressure Sensor

Examples of a basic automobile go back as early as the 1700s, with the design and engineering of steam-powered engines, built to transport humans. By 1806, the automobile industry started the production of engines running on fuel such as gasoline and petrol. Since 1985, the revolution of car design has resulted in creating a machine that is intuitive enough to make transportation as smooth and sophisticated as possible.

Modern-day vehicles – whether these take the form of a car, motorcycle, truck, aircraft, or boat – will all have an array of sensors embedded within the skeleton of a vehicle to animate and bring a fuel-powered structure to life. The scope of this article discusses oil pressure sensors as one particular sensor type in an automobile.

Functional Principle

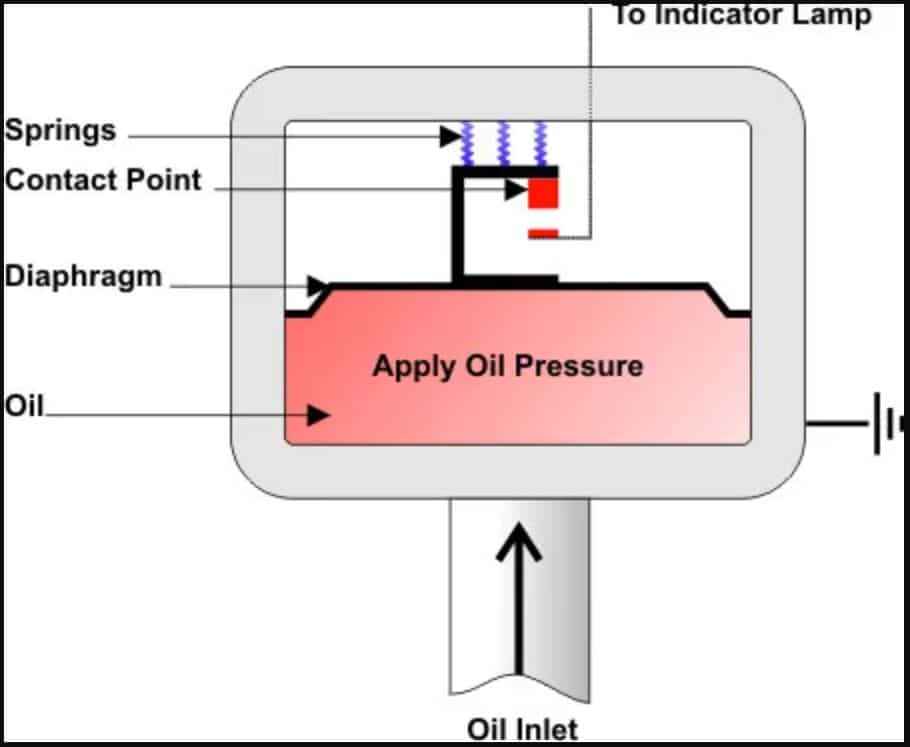

Standard oil pressure sensors work by displaying a warning signal when the oil pressure falls outside of the set range. Two important components to the oil pressure sensor include the spring-loaded switch and a diaphragm. The spring-loaded switch is connected to the diaphragm that is exposed to the oil pressure.

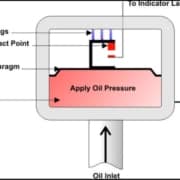

The pressure switch is mounted onto the side of an engine block and wired to an oil gallery. As the force of the oil pressure starts to build on the diaphragm, this force overcomes the switch spring pressure, which then pulls apart the electrical contacts to turn on the warning light. If the oil pressure falls below the set limit, the diaphragm releases pressure off the springs to close the switch contacts that would normally result in the display of a warning sign to the driver (Figure 1).

Figure 1. Working mechanism to an oil pressure sensor system. Image Credit: Clemson University

The low oil pressure indicator light is displayed on the dashboard of a vehicle. Any driver will know that when this light flashes continuously, it is indicating a momentary drop in the oil pressure. However, if this light remains switched on, the driver is alerted to a complete loss of oil pressure. So, when the engine to a vehicle is switched on, an electrical current travels from a fuse and straight to the oil pressure switch, making sure that the indicator light is ‘off’. When oil pressure starts to rise above 4.3 psi (per square inch), the diaphragm moves apart the contacts, thus switching on the oil pressure light.

Pressure Gauge Sensor

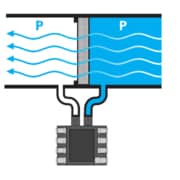

A low oil pressure warning light is one method used to alert the driver to fluctuations in the oil pressure levels. An alternative system for this purpose is known as a mechanical type pressure gauge component. There is a Bourdon tube inside a pressure gauge that tends to straighten out upon receiving pressure via a copper tubular component. The Bourdon tube is attached to a needle on the gauge, which moves as the tube begins to take a different shape. Movement of the needle across a scale on the gauge is used as a reference point to indicate changes in oil pressure inside the engine to a vehicle.

Sources and Further Reading

- Ribbens, W.B., Mansour, N.P. (2003). Understanding Automotive Electronics. USA, Massachusetts: Elsevier Science.

- Schwaller, A.E. (2005). Total Automotive Technology. USA, New York: Thomson and Delmar Learning.

- Hillier, V., Coombes, P. (2004). Fundamentals of Motor Vehicle Technology. UK, Cheltenham: Nelson Thornes Ltd.

- Knowles, D., Erjavec, J. (2005). TechOne: Basic Automotive Service and Maintenance. USA, New York: Thomson Delmar Learning.

For more information, visit this article on AZOSensors.com