Four Characteristics of Our Newest MEMS Sensing Element

Merit Sensor has owned and operated a wafer fab from its beginnings. Fabricating our own MEMS (micro-electro-mechanical systems) sensing elements, or die, is something that sets us apart from other pressure sensor manufacturers, many of whom source their MEMS die from foundries or suppliers. Producing our own wafers, which are diced into individual MEMS sensing elements, allows us to control our own technologies, development, and supply chain. To learn more about the advantages, read this AZoSensors interview with our director of engineering.

Since we continue to see interest worldwide in these MEMS sensing elements, we continue to develop MEMS die with superior performance at competitive cost. Our newest MEMS product on the market is the S Series, offering optimal size, sensitivity, and stability. Perhaps best of all is its excellent performance in regards to thermal hysteresis. Each of these characteristics will be discussed below.

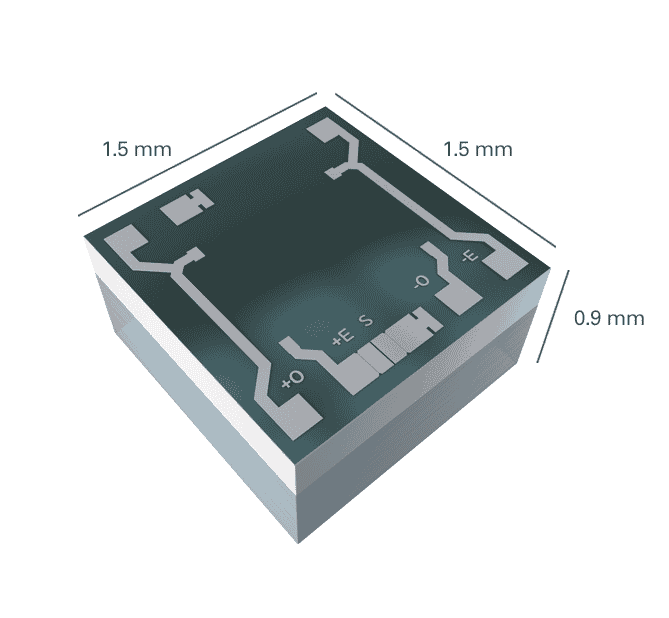

Size

One remarkable feature of the S Series is its solid performance at a very small size: 1.5 mm x 1.5 mm x 0.9 mm. This size also makes it is possible to optimize the amount of die produced on each 150 mm (6 inch) wafer. The end result is a lower-cost die for the customer without any loss of superior performance.

S Series MEMS Die Dimensions

Sensitivity

Silicon, which is the raw material of MEMS wafers, has piezoresistive properties, which means when pressure is applied, it is strained and its resistance changes accordingly. An output is based on the changes in resistance. Merit Sensor uses Wheatstone bridge technology to optimize the linearity of the output. It is challenging, however, to obtain an adequate output when the pressure is low. Nevertheless, through Merit Sensor’s proprietary MeritUltra technology the S Series provides a typical output at 5 psi / 34 kPa / 345 mbar of 100 millivolts (mV).

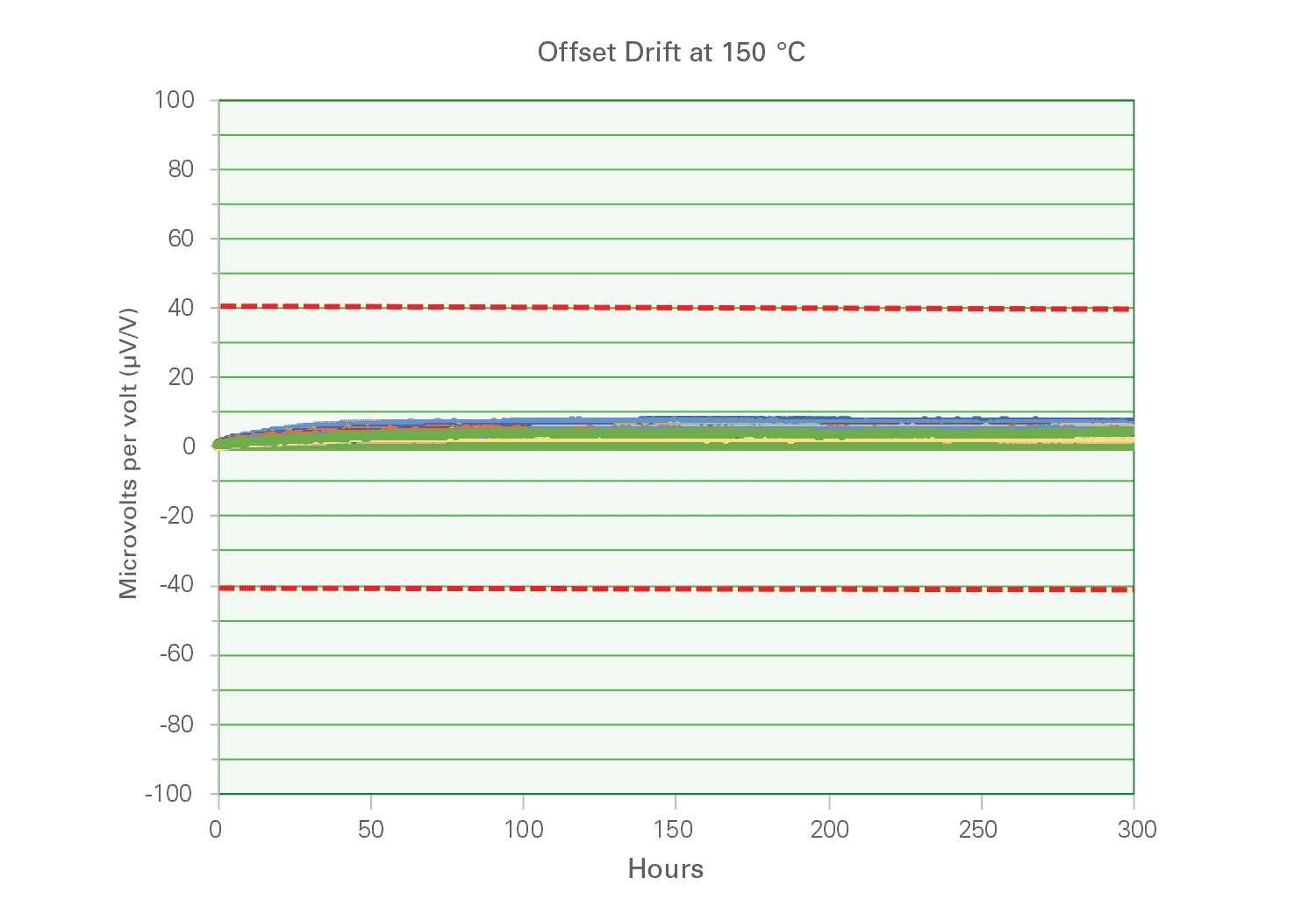

Stability

A stable part will remain accurate, i.e. it will not drift, over time and sustained temperature. The S Series data sheet specifies a long-term stability of ± 0.2 % of the full-scale output (% FSO). The chart below shows how stable and accurate the part has proven to be, demonstrating a typical offset drift of <0.05 % FSO at 300 hours.

Long-Term Stability of the S Series

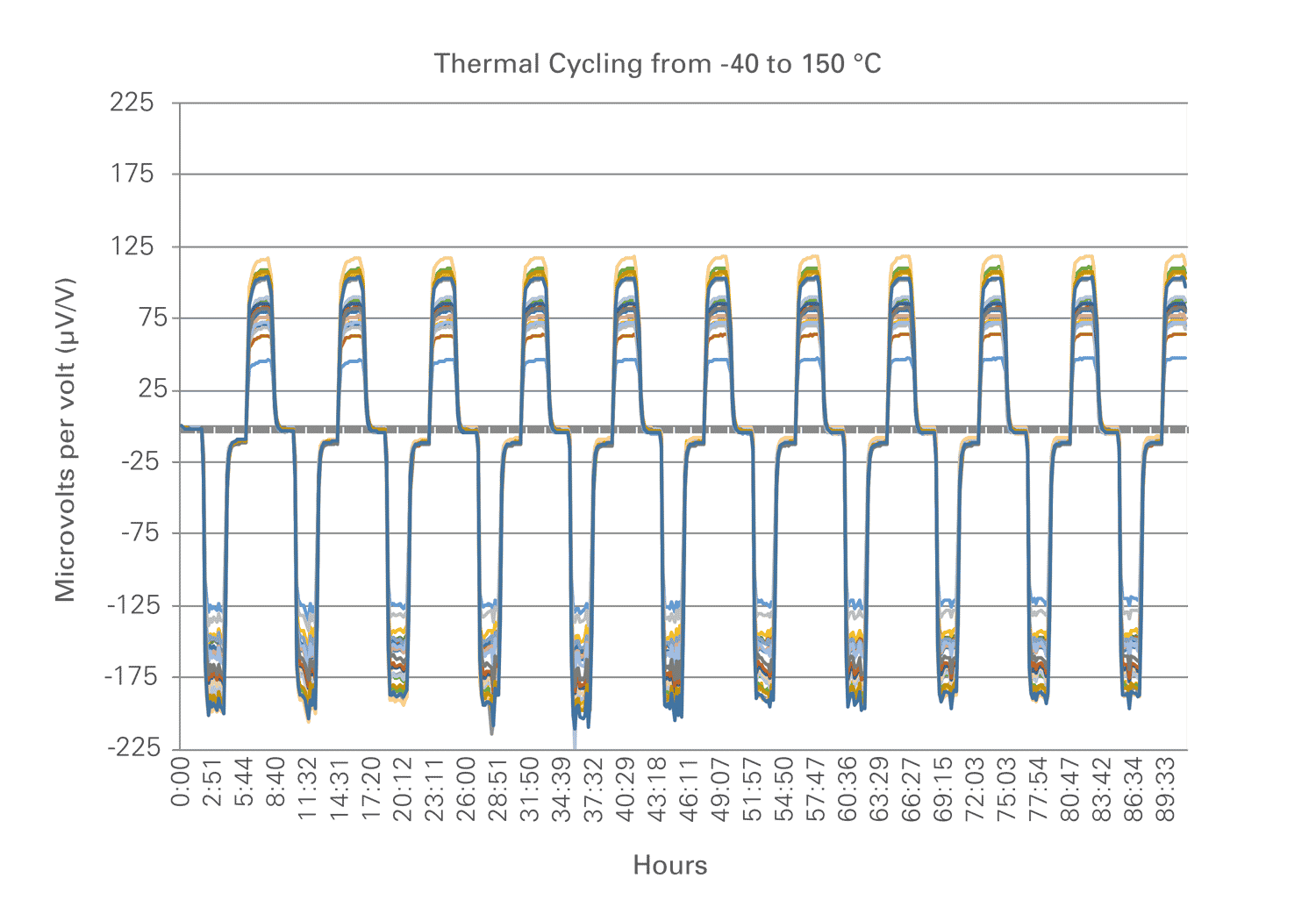

Thermal Hysteresis

The characteristic we are really talking about here, once again, is accuracy. In addition to remaining accurate over time and sustained temperature, the S Series displays exceptional accuracy when exposed to thermal cycling. A MEMS sensing element is inherently sensitive to temperature. Its resistance and output will change when temperature changes. Fortunately, changes that are consistent are simple to compensate. The S Series die exhibits very consistent, accurate output when it is exposed to extreme temperatures and returned to room temperature. In thermal cycling tests it demonstrated a typical thermal hysteresis offset of <0.05 % FSO.

Accuracy of S Series with Thermal Hysteresis

If you have any questions about using the S Series in your application, contact one of our sales managers. You might also find the application note “Handling of Mounting of Pressure Die” useful.