Understanding the Use and Function of MEMS Piezoresistive Pressure Sensors

In this interview, AZoSensors talks to Scott Sidwell, Engineering Manager at Merit Sensor Systems, about MEMS piezoresistive pressure sensors, silicon dies, and how these are all utilized across a range of industries.

Could you provide us with some background information on pressure sensors and their significance in various industries?

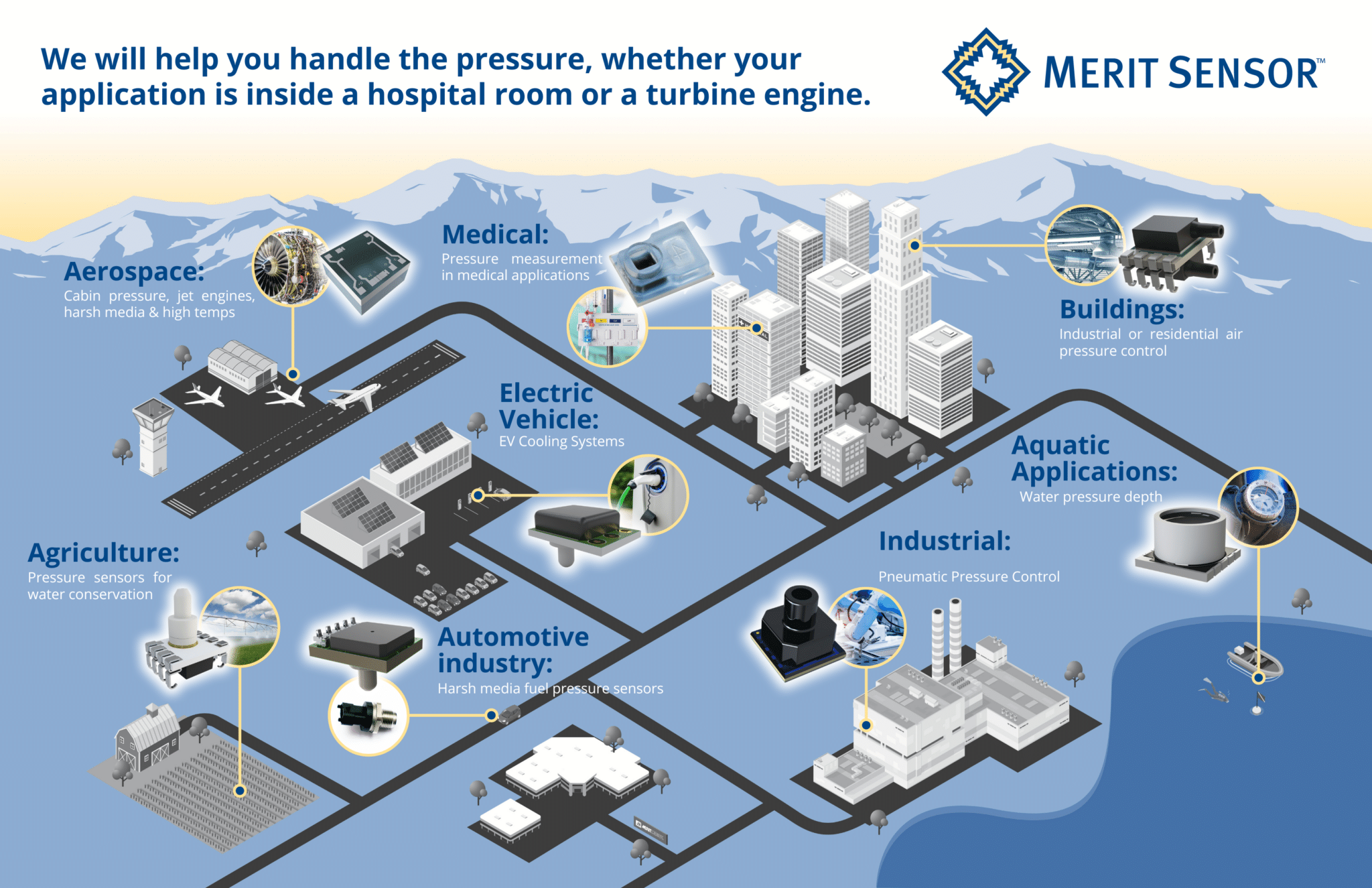

Pressure sensors are vital components that play a crucial role in various industries. The pressure sensor market is projected to see remarkable growth, as indicated by recent research, and it is expected to reach nearly 24.5 billion dollars by 2028.

They find applications in automotive, industrial automation and process control, consumer products like diving, e-bikes, and, importantly, in the medical field.

Pressure sensors work based on the principle of the force of a fluid divided by area. To put it into perspective, consider a syringe – a smaller one can generate more pressure than a larger one with the same force applied. Understanding this concept is crucial when dealing with pressure sensors.

Atmospheric pressure is a term we often hear. Could you explain what it is and its relevance in the context of pressure sensors?

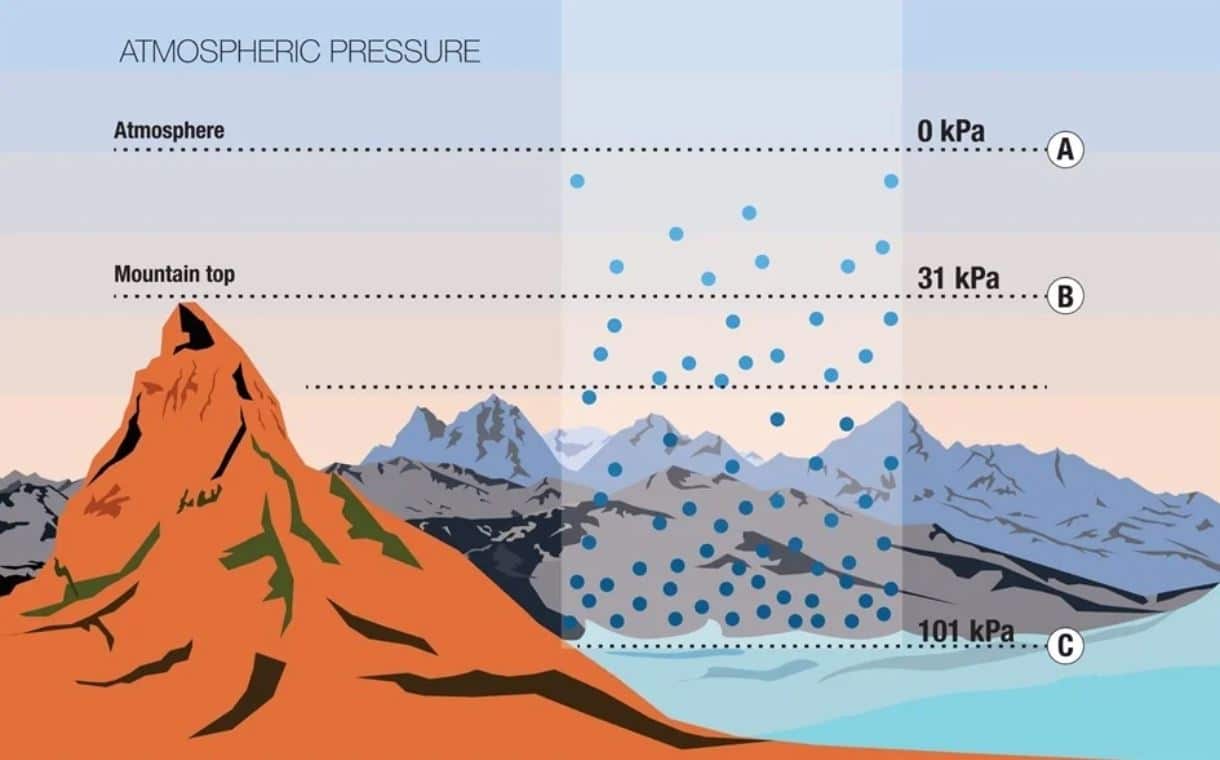

Atmospheric pressure is essentially the weight of the air pressing down on us. As you ascend in an airplane or spacecraft, the air becomes less dense, with fewer molecules and less oxygen. It is important to consider atmospheric pressure when measuring the pressure in your application, because it will determine the type of pressure sensor needed.

Image Credit: Mi Sketch/Shutterstock.com

What other applications besides the automotive industry benefit from pressure sensors, and how are they used?

Pressure sensors find applications across a diverse spectrum of industries, expanding far beyond their traditional use in the automotive sector. One of the sectors where pressure sensors play a critical role is the diving industry. In this field, pressure sensors are employed to monitor the depth of divers underwater, enabling them to calculate ascent and descent times accurately. The hostile underwater environment necessitates reliable pressure measurements to ensure diver safety.

Pressure sensors have made their way into the consumer product market. For instance, in the realm of bicycles, especially the emerging category of e-bikes, pressure sensors are integrated into various components. These sensors may be utilized on bike shocks, tires, and other critical parts to enhance the overall performance and user experience.

What are the typical applications of piezoresistive pressure sensors, and how do they work?

Piezoresistive pressure sensors are a subtype of pressure sensors known for their versatility and use in various applications. Piezoresistive sensors function on a principle involving doped, semiconductor silicon crystal, which allows them to measure pressure more repeatably than other technologies.

To understand their typical applications, it is worth highlighting that piezoresistive pressure sensors are not constrained to a single field. They are used in an array of industries, including the medical sector. In medical procedures like angioplasty, where surgeons inflate balloons inside arteries, pressure sensors play a crucial role. In these procedures, the pressure sensor’s output helps the surgeon monitor the level of inflation inside the balloon, and assess the overall status of the procedure.

Can you explain what MEMS technology is and its advantages in the context of pressure sensors?

MEMS stands for Micro-Electrical-Mechanical Systems, and there are many different types of MEMS. The deposition, ion implantation, and diffusion steps are all fundamental to semiconductor manufacturing, as well as the photolithography and etching of MEMS pressure sensors. MEMS pressure sensors feature an elastic silicon diaphragm, which means they are free from hysteresis and creep.

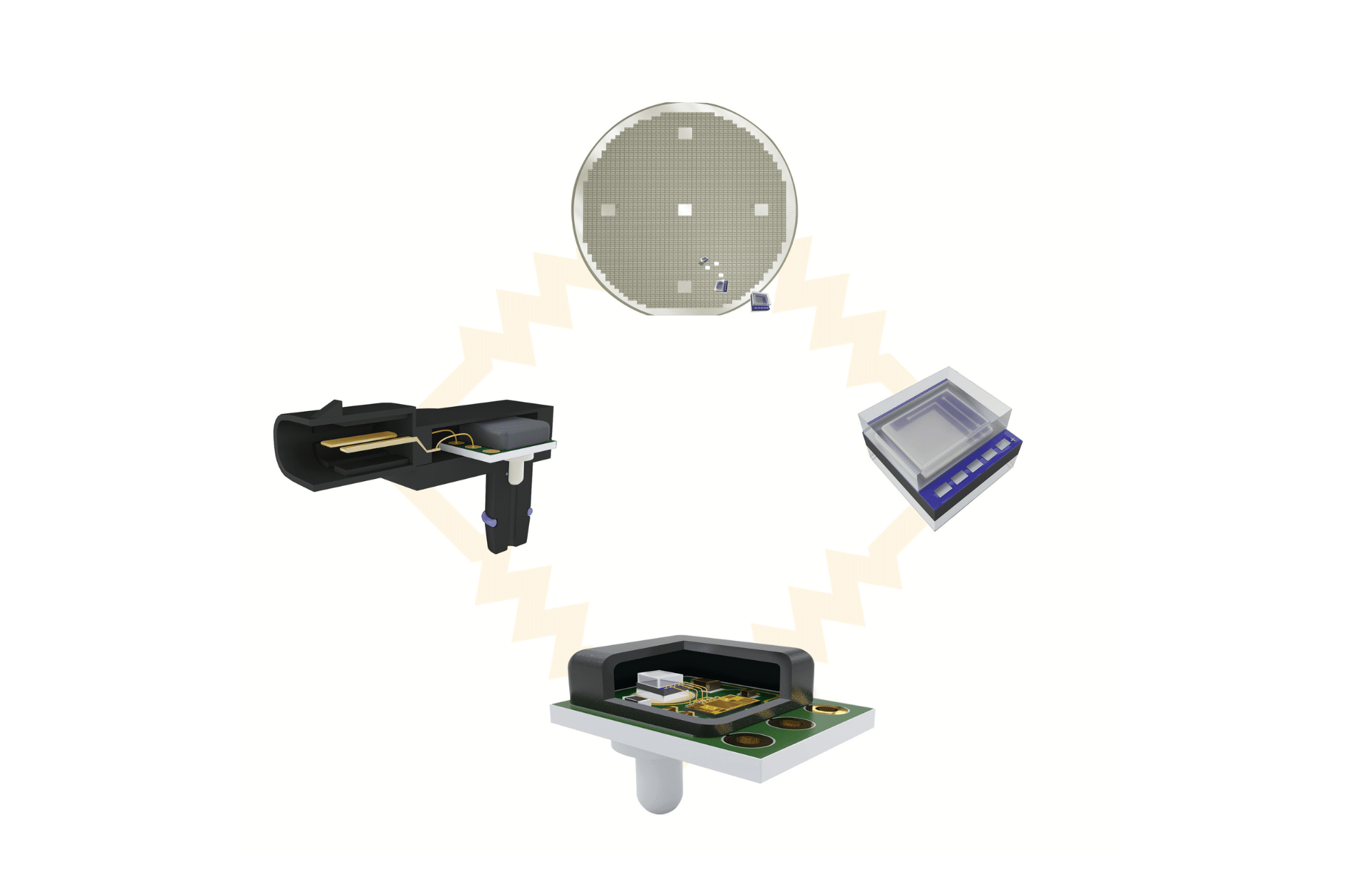

This elasticity benefits the sensor because it allows it to undergo repeated pressure cycling without altering its properties. When things tend to creep or change, it is almost always a result of how they are packaged, not necessarily the silicon chip itself. Putting thousands of pressure sensors onto one wafer also significantly helps to reduce costs.

Merit Sensor has its wafer fab in Utah. There are many advantages to working with a vendor that has its wafer fab. When it comes to developing a new product, having your wafer fab is a huge advantage, as it allows you to control the supply chain. Keeping the design in-house is often considered the key to the successful development and launch of any product.

Can you give us a basic understanding of the MEMS pressure sensor?

The key design characteristic of a MEMS pressure sensor is the Wheatstone bridge diffused into the silicon diaphragm. The change in output from this bridge corresponds to a change in applied pressure. When a customer needs a higher pressure range, the sensor requires a thicker diaphragm to handle the increased pressure. Conversely, for measuring low pressures, like inches of water or low pascals, a thin diaphragm suffices.

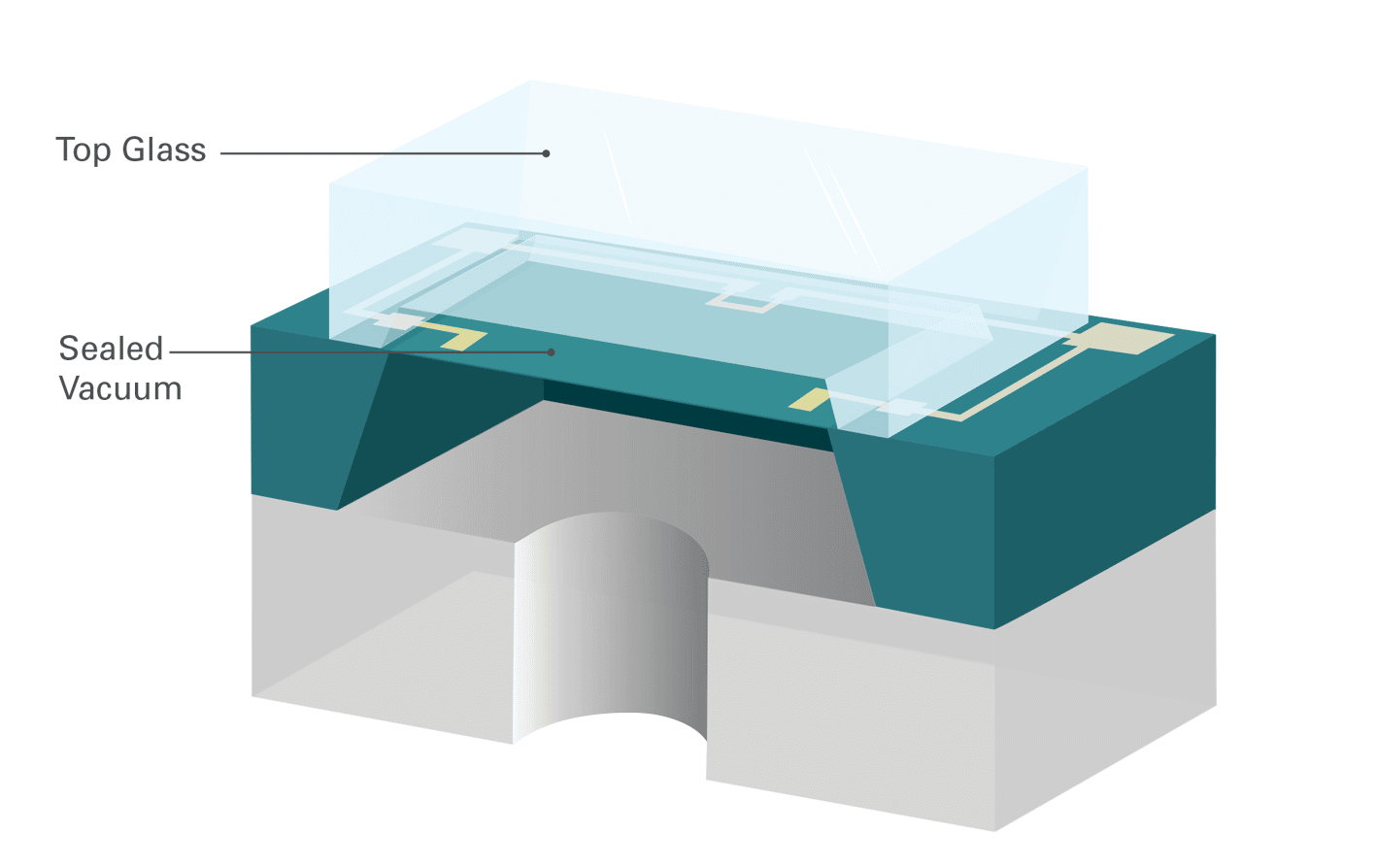

After the manufacturing process, the silicon is bonded to a piece of glass. The glass may have a hole to create a vent for various pressure applications, or it can be sealed without a hole. In the latter case, the glass and silicon are bonded together in a vacuum.

When there is no hole in the glass, it is known as an absolute sensor because the space between the silicon and glass represents zero pressure absolute.

There are two types of absolute sensors made from MEMS dies. The traditional type has no hole in the back glass, creating a sealed vacuum reference for absolute pressure. However, this design requires protection for the circuitry on the top side to prevent corrosion and shorts from humidity or moisture.

Alternatively, there is the absolute sensor with backside pressure. In this design, a piece of glass is added to the top of the silicon, creating a sealed vacuum reference on the top side and allowing for backside pressure on the MEMS element. This type is commonly used in automotive and high-temperature applications, as well as with liquids.

Can you tell us more about offset pressure and other factors like pressure non-linearity and hysteresis?

Offset pressure is the zero pressure measurement at room temperature. Pressure non-linearity measures how linear or nonlinear the sensor’s output is from zero pressure to full-scale pressure, and hysteresis reflects the difference between the initial zero and return zero, when pressure is applied and then relieved. The MEMS sensing element is designed to minimize these sources of error.

How do temperature-related factors, such as TCR and TCS, influence the behavior of pressure sensors?

It is possible to use the TCR, the Temperature Coefficient of Resistance, in conjunction with the pressure sensing to determine the temperature, because the TCR changes significantly with temperature. The Temperature Coefficient of Span/Sensitivity, or TCS, is important to take into account, especially in applications for wide operating temperature ranges. The TCS is negative, and when using the MEMS piezoresistive pressure sensor, the sensitivity or span decreases as the temperature rises.

Can you explain the importance of accuracy in pressure sensors and how it can be achieved?

Accuracy in pressure sensors is often measured as the total error band, which includes errors related to temperature and pressure. Achieving accuracy involves calibration, and fully compensated sensors with onboard ASICs simplify this process and provide higher accuracy. Accuracy is vital, especially in applications where precise measurements are critical.

How do stress and other external influences impact pressure sensors?

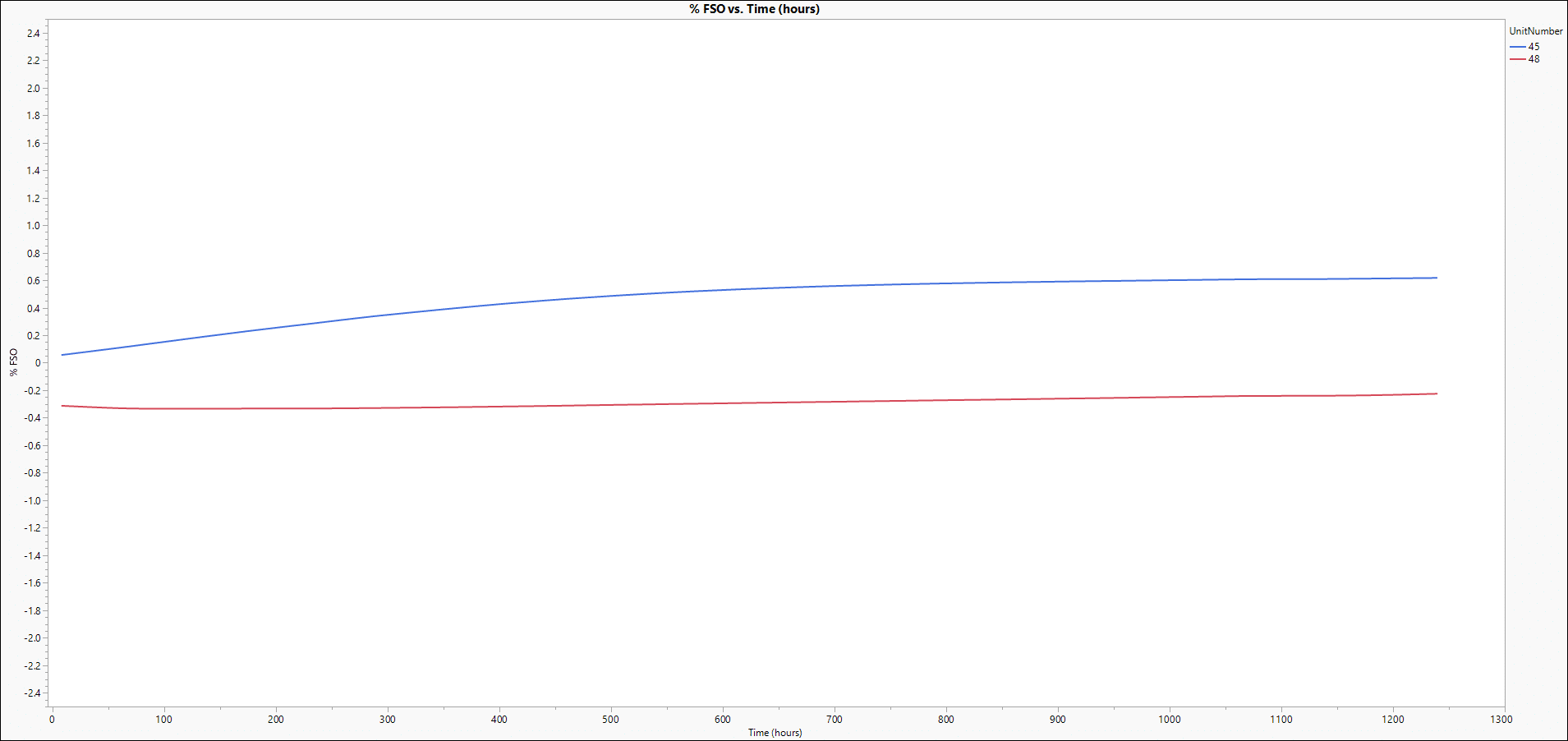

We take great pride in understanding and characterizing the sources of error that our customers can’t compensate for: thermal hysteresis and long-term stability. The last thing our customers want is a part failure in their hands, which can occur due to long-term stability issues.

It’s important to keep in mind, that the MEMS sensing element is also a good stress sensor. For example, a torque, or bending moment on the MEMS element will change the output of the Wheatstone bridge. Stress can be induced during packaging and assembly processes, impacting sensor performance. Over time, any package-related stresses will relieve themselves and come back to equilibrium. This stress-relief will manifest as a change in the offset of the sensor, in other words, offset drift and long-term stability. Careful handling and packaging are essential to maintain sensor stability.

Could you explain how MEMS dies are suitable for a wide range of applications, both specific and general, and what factors should customers consider when selecting a pressure sensor?

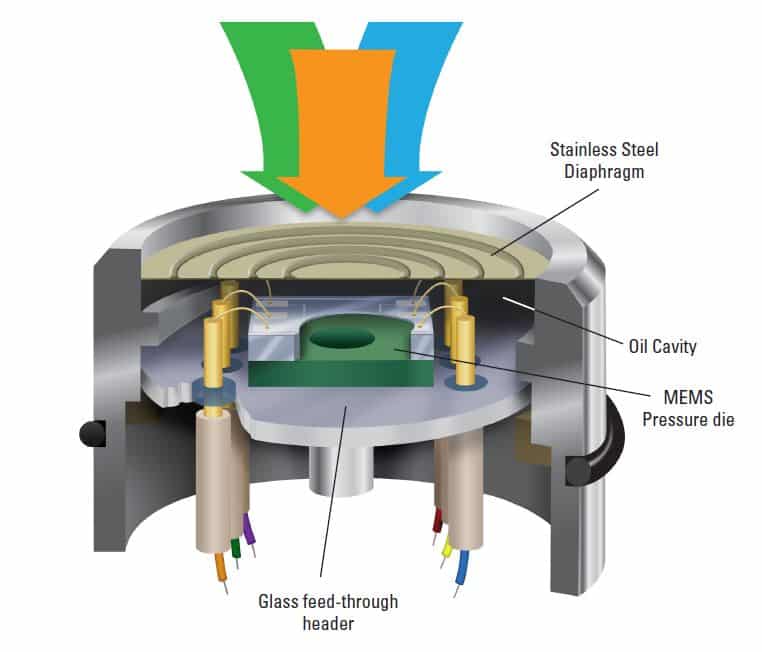

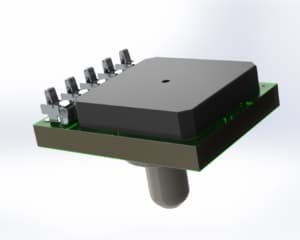

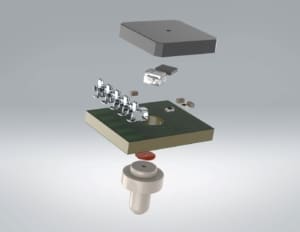

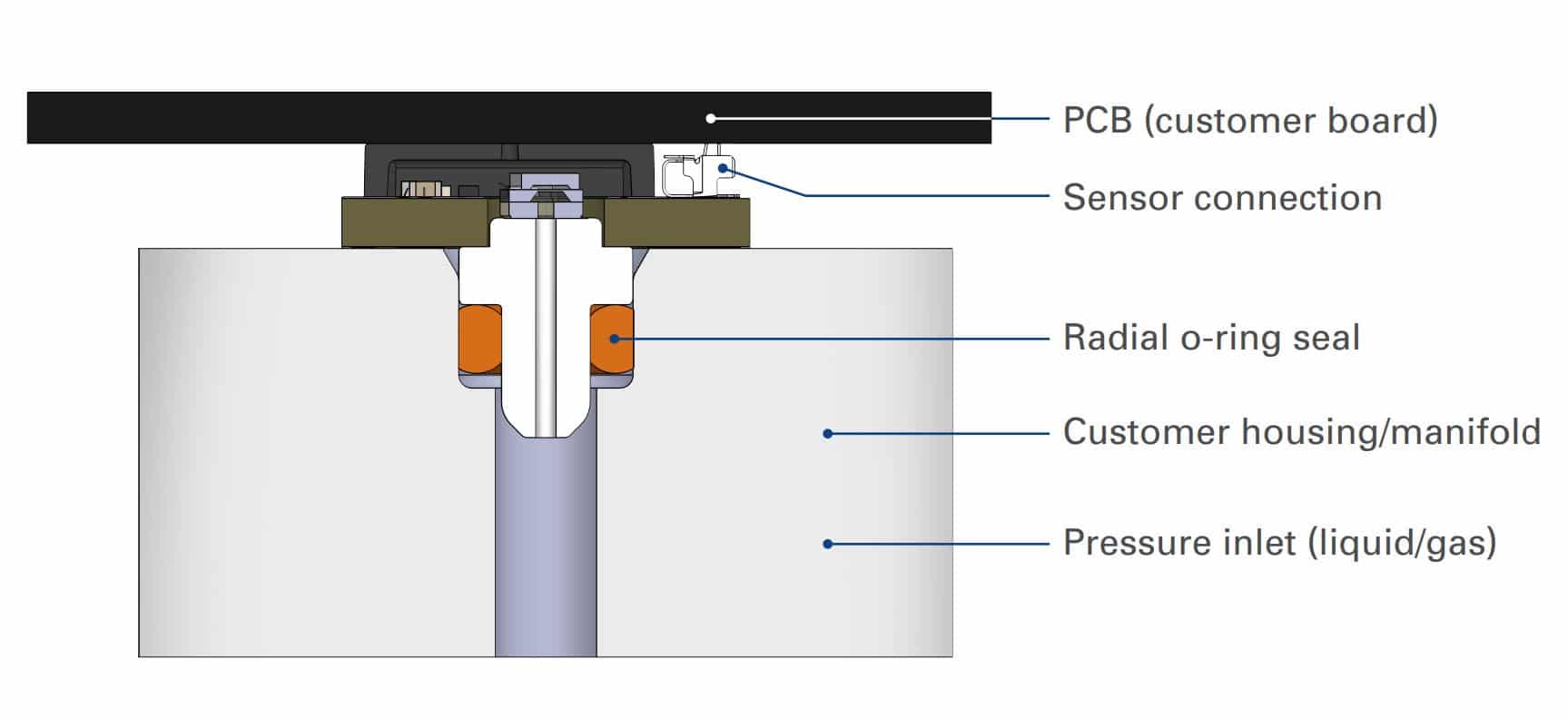

MEMS dies are common in pressure transducer or pressure transmitter applications where the MEMS die is on a header. The header gets welded into a stainless-steel housing with a stainless-steel diaphragm. Stainless steel is an excellent choice since it is very media-friendly, and most people are usually very familiar with stainless steel’s capabilities. This package is suitable for many industrial applications.

After welding the stainless-steel diaphragm and package together, there’s a back-filling of oil into this housing. A clean silicon oil surrounds the MEMS die, transmitting pressure between the stainless-steel diaphragm and the silicon diaphragm of the MEMS element.

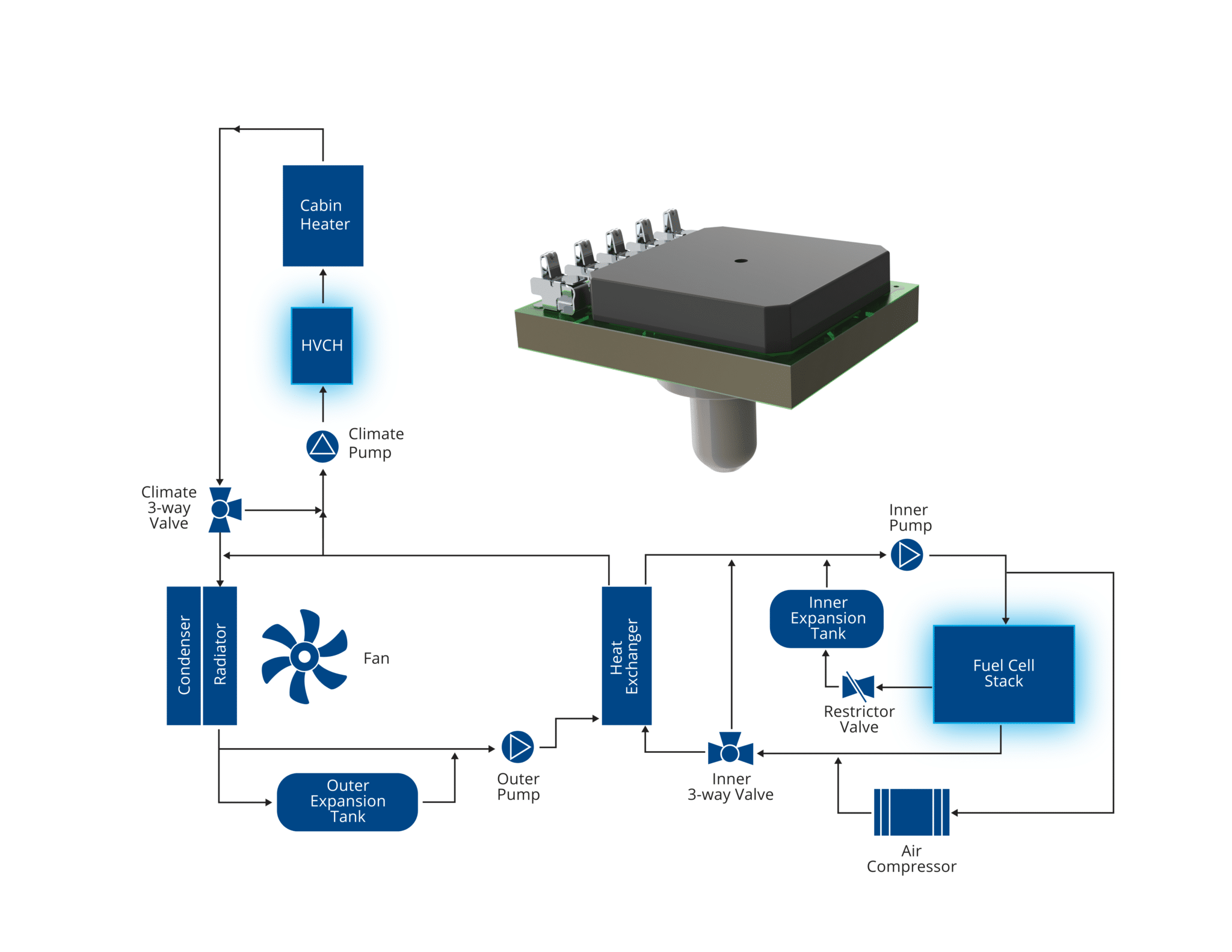

In the HVAC industry, the MEMS die can be purchased separately or packaged into our LP series and placed on a control board. These control boards are found in large buildings, either atop the building near the air intake or in the building’s utility room, where heat exchangers and air airflow systems are located.

Another common application is in transportation. Pressure sensors are widely used in various types of automobiles. This area continues to grow as legislation drives the demand for higher efficiency and cleaner emissions.

To learn more, watch the full webinar below:

Understanding MEMS Piezoresistive Pressure Sensors: A Close Look at a Silicon Die from Merit Medical on Vimeo.

About the interviewee

Scott joined Merit Sensor in September of 2003. Before joining Merit Sensor, he worked in a variety of engineering roles with semiconductor companies, such as ON Semiconductor and Motorola. In his current role he works closely with customers to provide pressure-sensing solutions and technical support.

Scott received a chemical-engineering degree and MBA from Brigham Young University. He speaks Spanish and enjoys volunteering his time.