Three Common Types of Pressure-Sensor Packages

At the heart of every MEMS pressure sensor is a MEMS silicon die. Merit Sensor owns and operates a wafer fab, where it produces all of its own MEMS die. Packaging a MEMS die requires specialized equipment and skills to handle the small and sensitive die and to perform delicate wire bonding. Therefore, many customers purchase pressure-sensor packages, in which the die have already been mounted and wire bonded. This article will discuss Merit Sensor’s three types of packages: uncompensated, passively compensated, and fully compensated.

Uncompensated

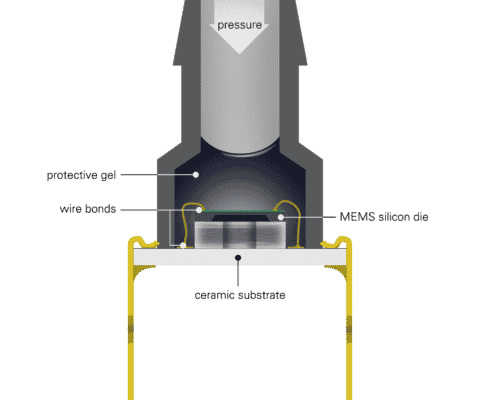

The most basic pressure-sensor package is uncompensated. In an uncompensated package the MEMS die has been mounted to a ceramic substrate with a special die-bond material, wire bonded to electrical traces on the ceramic, and covered with a protective cap or gel. Since each silicon die is inherently unique, the output for each one will be unique. Fortunately, silicon die have outputs that are very repeatable. This means the output can be compensated.

PMD Series Pressure Sensor – Uncompensated

To get an accurate output, the customer will need to perform some degree of compensation. Certain applications lend themselves to compensation performed by the customer. Factors that will often determine whether the compensation is performed by Merit Sensor or the customer include the following:

- Cost

- Accuracy

- Size

- Output signal

Passively Compensated

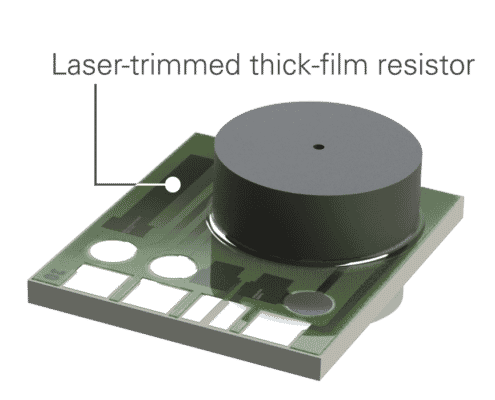

A more ready-to-use version of a pressure-sensor package, especially for use at room temperature, is one with passive compensation. In this case the pressure-sensor package is basically the same as an uncompensated package; however, the thick-film resistors on the ceramic substrate have been laser trimmed, providing adequate compensation of the die’s output in operating temperatures between 10 °C and 40 °C.

AP Series Pressure Sensor – Passively Compensated

For applications, such as invasive blood-pressure monitoring in a hospital room, compensation in this temperature range is sufficient. Other benefits of passive compensation are the pure analog signal with practically infinite resolution and frequency response times in microseconds.

Fully Compensated

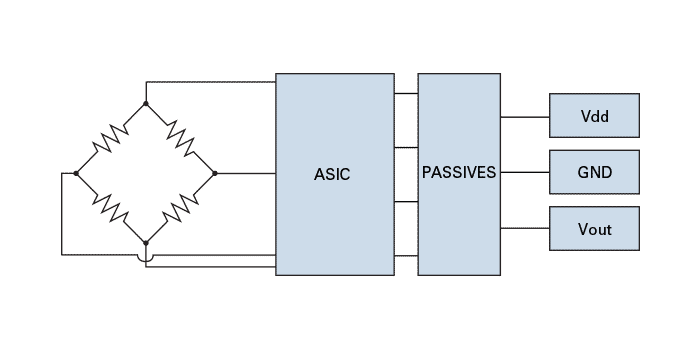

In a fully compensated pressure-sensor package, signal conditioning (an on-board ASIC) is used to compensate the die’s output across a wide temperature span. A MEMS silicon die does not know the difference between pressure and temperature, so this level of compensation is especially critical in applications where the temperature of the sensing environment fluctuates drastically or reaches extremes highs or lows. Compensation through signal conditioning can provide a linear output and make that output as accurate as ±1 percent of the full-scale output (±1 %FS total error band) in operating temperatures between -40 °C and 150 °C.

Wheatstone Bridge on a MEMS Die with an On-Board ASIC

If we use fuel pumps in airplanes and fuel rails in vehicles for examples, it is typical for pressure sensors to be exposed to extreme temperatures; nevertheless, it is essential that these pressure sensors offer an accurate output. A fully compensated pressure sensor would be the appropriate solution.

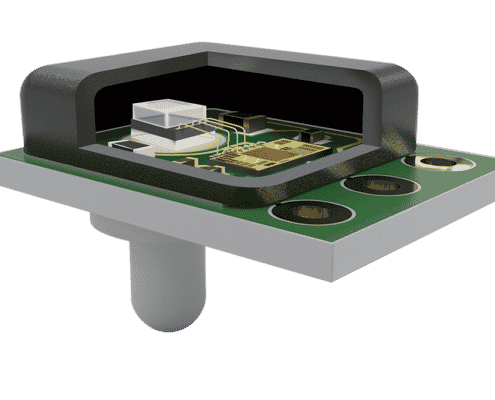

TVC Series Pressure Sensor – Fully Compensated

It is important to emphasize that each pressure sensor will require individual compensation, as each one will have a unique output inherent to its MEMS die. Many customers simply do not have the time or equipment to do this logistically or economically to each unit passing through their assembly line.

Merit Sensor has the experience and equipment to handle this necessary step for the customer. Furthermore, it often, although not always, makes sense for compensation to be done before the part leaves our facility. Nevertheless, we have left options for those customers who choose to do their own compensation. As always, our sales managers and technical team will be happy to answer any related questions.