Exploring the CMS Series: Pressure Sensors in Analyzers and Ventilators Revolutionizing Healthcare and Environmental Monitoring

During the COVID-19 pandemic, several medical papers exposed the risk of barotrauma from mechanical ventilation, bringing into focus the value of precise pressure sensor technologies.1,2,3 Yet the utility of pressure sensors extends beyond medical applications, complementing pneumatic systems, electronics, and dry, non-corrosive gas pressure tools.

The CMS Series of pressure sensors, manufactured by Merit Sensor, provides high-performance solutions for all these applications. This article explores these sensors in the context of analyzers and ventilators, explaining why they represent the preferred choice for medical professionals, engineers, scientists, and industry leaders worldwide.

Analyzers and Ventilators: In a Nutshell

Analyzers encompass a broad range of devices used to measure and profile various substances, such as gases, liquids, and blood samples. These devices play a crucial role in diagnostic, environmental monitoring, and quality control applications. Some key examples include blood gas analyzers, gas chromatographs, ECMO machines and other systems like air quality monitors equipped with analyzers to track pollutants and ensure optimal indoor air quality. To ensure these systems operate within ideal parameters, pressure sensors are incorporated to monitor and regulate airflow and pressure levels.4

On the other hand, mechanical ventilators are specialized devices designed to assist with a patient’s breathing. These machines deliver positive pressure ‘breaths’ to the lungs, ensuring effective oxygen circulation and carbon dioxide expulsion. Ventilators carefully regulate airflow based on patient-specific settings, such as pressure, volume, and breathing rate, to fully support or augment spontaneous breathing. Precise pressure sensors are also critical to their operation, maintaining the correct air pressure and preventing complications such as barotrauma.5

Enter the CMS Series by Merit Sensor

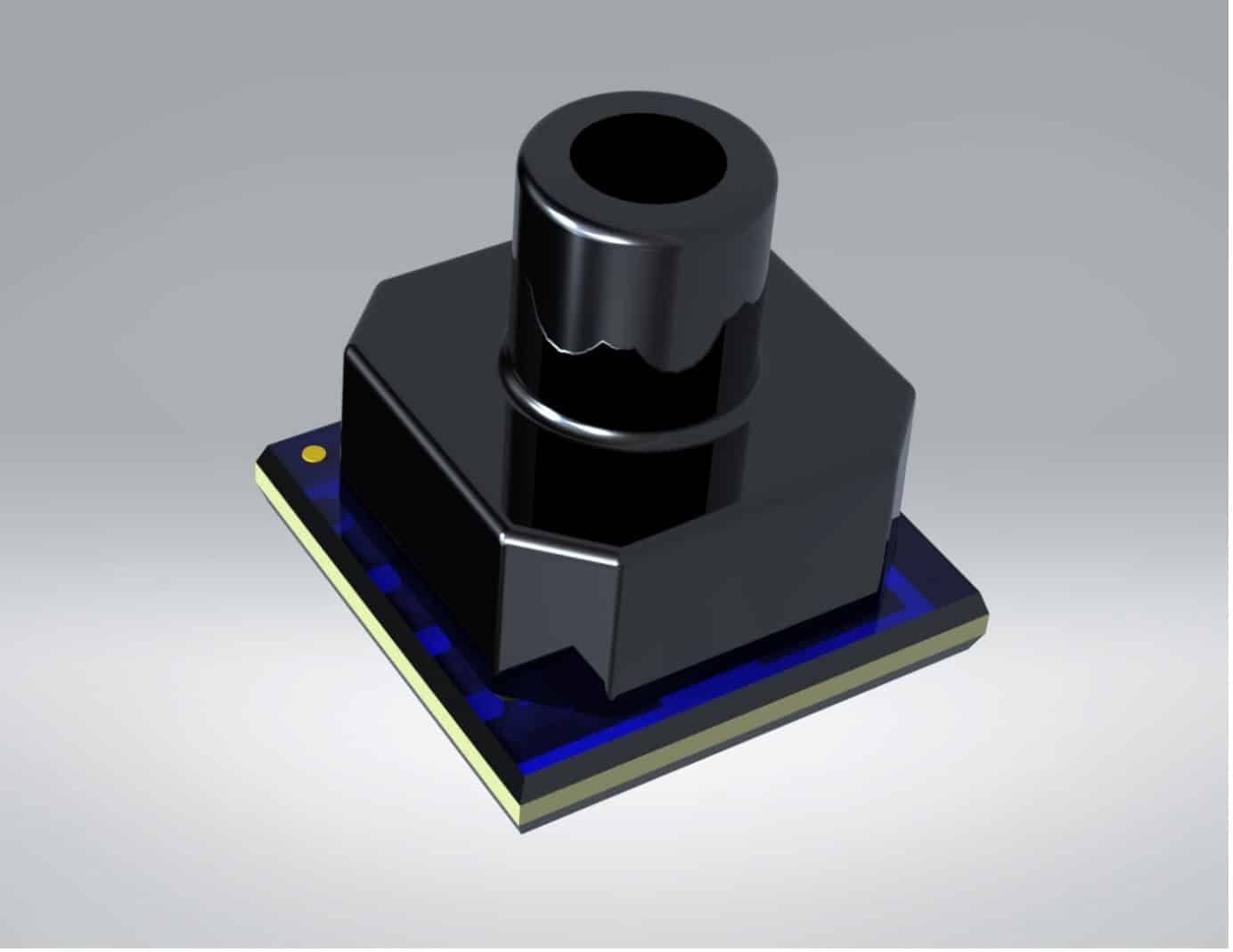

The CMS Series by Merit Sensor is a high-performance pressure sensor designed for precision and reliability. Utilizing an ASIC for calibration and thermal compensation, this sensor guarantees long-term, accurate pressure responses. It features a piezoresistive Wheatstone bridge with glass bonded to a chemically etched silicon diaphragm, which allows the sensor to maintain stability across various environmental conditions. Its compact size, wide operating voltage range, and low power consumption make it valuable across numerous applications. With absolute and gage pressure options, the CMS Series is suitable for a range of pressure-sensing needs, offering both I2C and SPI digital outputs.

Merit Sensor, based near Salt Lake City, Utah, designs, engineers, and manufactures its products in-house, assuring quality control from start to finish. The company’s proprietary Sentium® technology provides best-in-class temperature stability, allowing sensors like the CMS Series to perform steadfastly under challenging conditions. This comprehensive approach to development and production positions Merit Sensor as a leader in high-precision pressure sensing solutions.6,7

CMS Series: Specification Breakdown

The unique profile of the CMS Series sets it apart from other pressure sensors on the market, making it the go-to choice for both analyzers and ventilators.

-

High Precision

Whether using analyzers or ventilators, extreme precision is required to generate data that reliably reflects sample conditions. With an accuracy of ±0.25 % full-scale output, the CMS Series offers pinpoint pressure measurements and peace of mind in situations where minor deviations affect performance and patient outcomes.4

-

Durability and Stability

Engineered with a robust silicon piezoresistive element, these sensors provide long-term repeatability and can operate in demanding outdoor conditions and healthcare environments. Their stable performance over time reduces the need for frequent maintenance or recalibration.6

-

Wide Pressure Range

The CMS Series covers a broad spectrum of pressures—from -2 to 150 psi—accommodating the needs of both high- and low-pressure applications. This versatility makes it suitable for a wide variety of devices and industries.4

-

Compact Design

At only 6.8 mm x 6.8 mm, the CMS Series is small enough to be easily integrated into compact devices without compromising on performance. This is a significant advantage for manufacturers designing portable or space-constrained equipment, such as hand-held analyzers.4

-

Temperature Compensation

CMS Series sensors are equipped with temperature compensation over a range of -40 °C to 85 °C, making them reliable even in fluctuating environmental conditions.7

-

Low Power Consumption

Efficient power use is essential in devices like ventilators that need to operate continuously and for battery-powered analyzers that are used in the field. The CMS Series’ low power mode ensures minimal energy consumption without sacrificing performance.6

-

Domestic Manufacturing

All CMS Series products are proudly manufactured in the US, ensuring the highest standards of quality and compliance with local regulations.4

-

RoHS Compliant

All products are Restriction of Hazardous Substances (RoHS) compliant, meeting the specific environmental safety standards set by the European Union.6

The CMS Series by Merit Sensor: A Benchmark for Precision and Performance

The CMS Series harnesses the latest pressure-sensing technology, blending innovation with precision, to deliver unrivaled performance. With its advanced design, offering temperature compensation and energy efficiency, it serves as a critical component in life-saving medical devices like ventilators as well as environmental analyzers.

Manufactured in the US with a commitment to superior quality, the CMS Series is engineered to adapt to evolving needs. Its versatility ensures that professionals worldwide, from engineers to healthcare providers, can trust it to perform under the most demanding conditions.

Contact a member of the Merit Sensor Systems team today to learn more!

References and Further Reading

- Serck, N., et al. (2023). Barotrauma in COVID-19 acute respiratory distress syndrome: retrospective analysis of the COVADIS prospective multicenter observational database. BMC Anesthesiology. doi.org/10.1186/s12871-023-02093-1

- Belletti, A., et al. (2021). Predictors of Pneumothorax/Pneumomediastinum in Mechanically Ventilated COVID-19 Patients. JVCA. doi.org/10.1053/j.jvca.2021.02.008

- Rajdev, K., et al. (2021). Pulmonary Barotrauma in COVID-19 Patients With ARDS on Invasive and Non-Invasive Positive Pressure Ventilation. Journal of Intensive Care Medicine. doi.org/10.1177/08850666211019719

- CMS Series technical datasheet

- Hickey, S.M., et al. (2024). [Online] Mechanical Ventilation. StatPearls [Internet]. Available at: https://www.ncbi.nlm.nih.gov/books/NBK539742/ (Accessed on 21 October 2024).

- Merit Sensor. CMS Series: Data Sheet. Available at: https://meritsensor.com/assets/documents/pdf/CMS-Series.pdf

- Merit Sensor. [Online] CMS Series – Available Now! Available at: https://meritsensor.com/products/cms-series/ (Accessed on 20 October 2024).