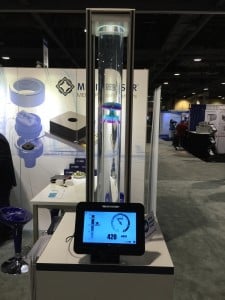

Rick Russell Addresses the Micro Nano Technology Special Interest Group at the University of Utah

Merit Sensor’s president, Rick Russell, spoke recently as the keynote speaker for the Micro Nano Technology (MNT) Special Interest Group to a group of approximately 80 U.S. college educators gathered at the University of Utah. The event is “a venue to share ideas and learn from others who work to educate technicians, a place to stay on the forefront of industry and workforce needs, and a forum to network and share ideas on ways to strengthen and augment workforce development programs through educational partnerships with industry for tomorrow’s micro and nano technology workforce” (MNT 2017 Special Interest Group Program).

Rick Russell, President of Merit Sensor, was presented with a 6-inch wafer as a token of appreciation for addressing the Micro Nano Technology Special Interest Group at the University of Utah on July 18, 2017.

With over 20 years of experience working with MEMS (microelectromechanical systems), Rick has valuable industry insight to offer educators and their students. In his speech he emphasized the importance of teachers stimulating students’ interest in science and experimentation and the importance of pulling some of the less-than-stellar students out of their shells because, he argued, they are sometimes the most valuable employees in the workplace. “I can’t say enough,” he said, “about getting the kids involved.” Organizations like the Micro Nano Technology (MNT) Special Interest Group are important to companies, like Merit Sensor, that value the way students are educated and encouraged. Some of the students could end up working in the field of MEMS pressure sensors and even for Merit Sensor.

The workforce at Merit Sensor by in large comprises electrical, mechanical, and chemical engineers; technicians; and operators. The company is highly dependent on technical knowledge and skills and, therefore, looks to today’s students to bring fresh knowledge and enthusiasm to help it stay at the forefront of the industry in the face of tomorrow’s challenges.