Honoring the Legacy and Embracing the Future at Merit Sensor

Merit Sensor Systems, part of the Merit Medical Systems family, has grown into a trusted global leader in MEMS (micro-electromechanical systems) piezoresistive pressure sensors. These tiny but powerful components lie at the heart of many of Merit Medical’s devices, supporting industries worldwide and giving physicians confidence when it matters most.

Recently, Merit Medical announced the retirement of its founder and longtime CEO, Fred Lampropoulos. While Fred will continue serving as Chairman of the Board, this moment marks a shift in our story, moving from founder-led to founder-inspired. As such, it is a fitting time to reflect on the vision, drive, and leadership that shaped both Merit Medical and Merit Sensor into the successful establishment that it is today.

Where it All Began: From an Idea to Reality

Fred’s entrepreneurial path started with one simple but important idea: making disposable syringes safer and stronger.

In 1987, he founded Merit Medical in Murray, Utah, and within a year, the company’s first syringe was on the market. That single innovation became the foundation of a portfolio that has since grown to more than 2000 proprietary medical devices, tools used every day in interventional, diagnostic, and therapeutic procedures around the globe.

Central to Fred’s leadership was “The Merit Way”—a philosophy built on vertical integration, reinvention, and above all, a commitment to improving patient outcomes. Guided by this vision, Merit expanded to employ more than 7000 people worldwide, supported by an international sales and clinical team dedicated to ensuring products reach physicians and hospitals wherever they’re needed.

The Birth of Merit Sensor

Another key chapter in Fred’s story was the creation of Sentir Semiconductor in 1991. His goal was to support a new angioplasty inflation device with advanced pressure-sensing technology. By 1993, Sentir’s first pressure sensor was in production, and just four years later, annual sales had passed the one-million-unit mark.

In 1999, the company became part of Merit Medical, and by 2002, it officially took the name Merit Sensor Systems. Two years later, a new wafer fabrication facility was completed in Salt Lake City, featuring a leading-edge ISO 5 cleanroom. By managing its own sensor production and calibration, Merit Sensor gained a lasting advantage in its ability to deliver reliable, scalable, and flexible solutions for industries around the world.

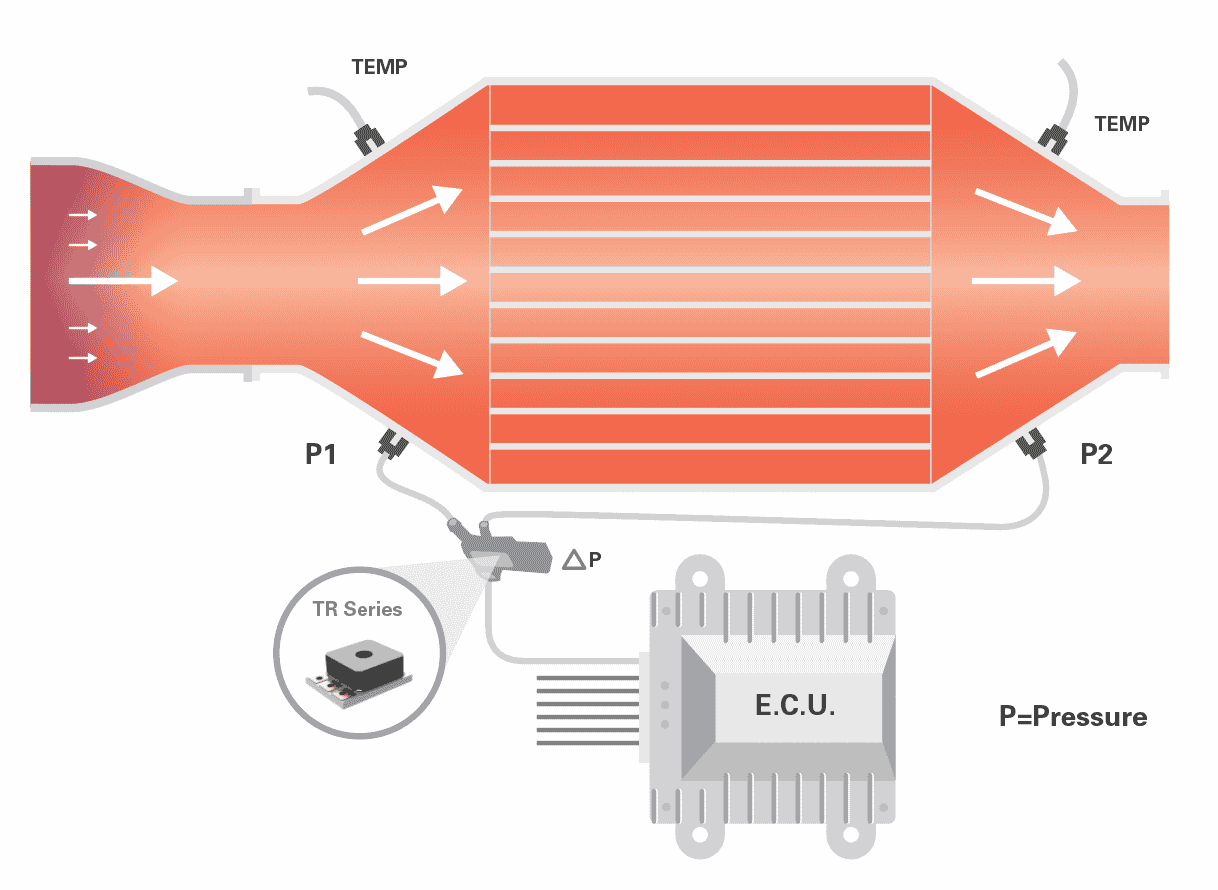

Today, those sensors support not only Merit Medical devices but also a wide range of applications in aerospace, transportation, industrial systems, and consumer electronics. Wherever precision, reliability, and safety are critical, our sensors are trusted to deliver.

Pressure Sensors: The Sentinels within Life-Saving Devices

Merit Sensor technology plays a central role in many of Merit Medical’s flagship products. Devices like the DiamondTOUCH™ Digital Inflation Device, used in angioplasty, and the Blue Diamond™ Digital Inflation Device, which combines digital accuracy with analog simplicity, rely on highly accurate pressure sensing to give clinicians precise control.

The MONARCH® Inflation Device, used in biliary dilation, integrates the same sensor technology with timing features that enhance patient safety during delicate procedures. Our Meritrans® Blood Pressure Transducers also stand out, providing reliable, customizable solutions for hospitals and labs, designed to integrate seamlessly with fluid management systems.

Together, these devices showcase how Merit Sensor technology underpins the accuracy, reliability, and safety physicians depend on, and ultimately, how patient lives are safeguarded every day.

The Merit Way: A Culture of Excellence

All these years later, Fred’s philosophy, The Merit Way, continues to shape the culture at Merit Sensor. At its core is our H.E.A.R.T.:

- Health: Prioritizing employee well-being and patient outcomes

- Excellence: Striving for the highest standards in design, production, and service

- Agility: Staying responsive to challenges and opportunities

- Responsibility: Owning the impact of our work and decisions

- Teamwork: Collaborating across teams and divisions to achieve shared goals

These values have fueled our growth and fostered a culture of continuous improvement and shared purpose.

A Legacy That Extends Beyond Business

Fred’s impact can also be seen beyond the balance sheets and product lines. Drawing on the discipline he learned as a former US Army Special Forces officer, his career has spanned nearly four decades, during which he filed over 200 patents, earned multiple industry honors (including the Utah Governor’s Medal for Science and Technology), and was inducted into the Utah Business Hall of Fame.

But the biggest, and arguably best, legacy he has left behind is his unwavering commitment to giving back to the people. Through support for education, healthcare initiatives, and community programs, Fred has left a lasting impact not just in Utah but worldwide. His leadership has touched employees, shareholders, families, and patients alike.

Looking Ahead

As Merit Medical and Merit Sensor turn over a new leaf and start their new chapter, continuity and stability will remain at the forefront. Fred will still be Chairman of the Board, while Martha Aronson has been appointed CEO and President. Fred has spoken with great confidence about Martha’s leadership, describing her sharp thinking, collaborative approach, and alignment with The Merit Way.

At Merit Sensor, we’re proud to carry that same spirit forward. The values that got us here—commitment, innovation, and keeping people at the heart of everything we do—are still what guide us today, just as they did when we started with a single syringe. Similarly, the MEMS pressure sensors developed in Salt Lake City will continue to power life-saving devices, while the culture of growth and responsibility ensures new breakthroughs will follow.

For employees, customers, and patients alike, Fred’s impact continues to inspire, and his dedication to saving lives will live on in every device that bears the Merit name.