Pressure Sensor for Extended Temperatures

A number of pressure sensor applications in harsh environments such as industrial, automotive, aerospace and even medical equipment present developers with contradictory requirements that result in expensive compromises. Generally, these sensors are employed to measure flow, level and pressure of harsh fluids such as refrigerant, oil, gas or other caustic solvents that can damage the sensor element. Additional challenges arise as a result of extended temperature requirements, even beyond compensation for accurate pressure readings.

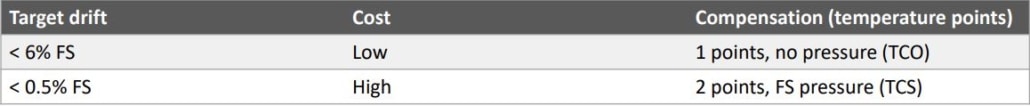

Aerospace and automotive specifications are particularly stringent, with operating temperature ranges as wide as -40 °C to +150 °C. And these rugged applications usually have high accuracy and reliability requirements, as component failure can result in safety risk or product recalls. To respond, equipment manufacturers depend on expensive ongoing maintenance and component replacement to work around the inherent short lifespan of the sensor.

Challenges

Despite the fact that the packaging of the sensor component is important in solving this issue, it is a challenge that has, until lately, eluded sensor manufacturers. Consider a typical use case. An automotive application such as gas or diesel fuel-line sensing requires a sealed sensor element that can be installed within the fuel line to sense pressure changes that signify a plugged fuel filter, which offers a feedback signal to the car’s computer to warn the driver. Airplane engine, valve controls and gear, and leak-detection systems or measurement and control of compressors in industrial equipment usually have similar requirements. While medical applications may not demand the pressure sensor be operated in fluids as severe as gasoline, eventually even saline solution can be corrosive, and the cleaning and sterilization process typically needs repeated contact with caustic chemicals such as bleach.

The main issue is that the adhesives that are employed to make the pressure seal and protect the sensor die and related circuitry ultimately soften in the surrounding fluid. The sensor circuitry is broken, as soon as the seal breaks, thus creating a familiar reliability failure that can be high-priced if it causes a product recall or requires regular maintenance and replacement of the sensing subsystem.

The difficulty in packaging is further increased because of the extended temperature requirements. Despite the fact that some latest adhesives are capable of withstanding higher temperatures than was feasible in the past, humidity can destroy the bond strength of most adhesives and they still risk die detachment at pressures of 300 psi. Although there are exotic epoxies that can withstand some humidity and temperature extremes, storage and application lead to additional manufacturability issues, and these epoxies are capable of affecting accuracy of the sensing element in extended temperature applications.

Solution

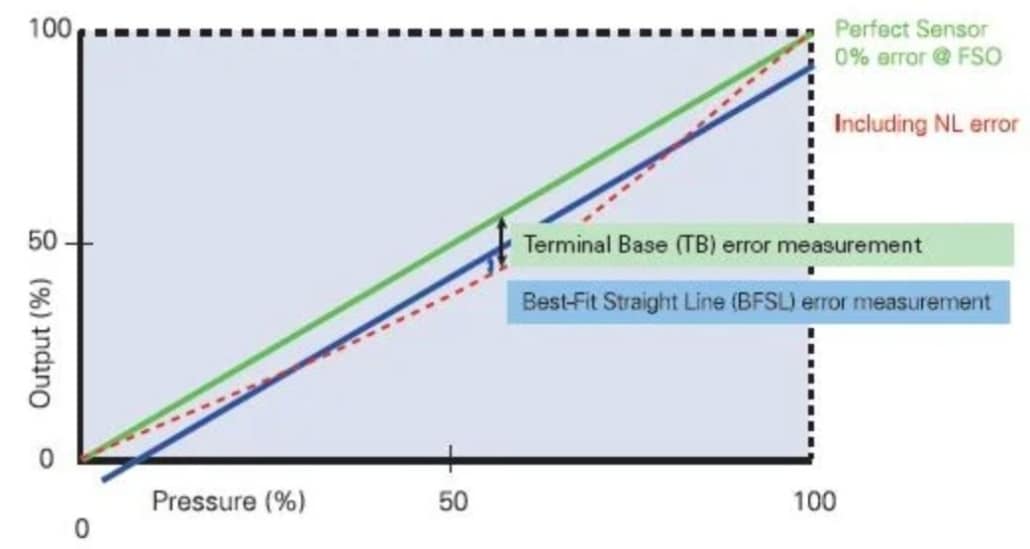

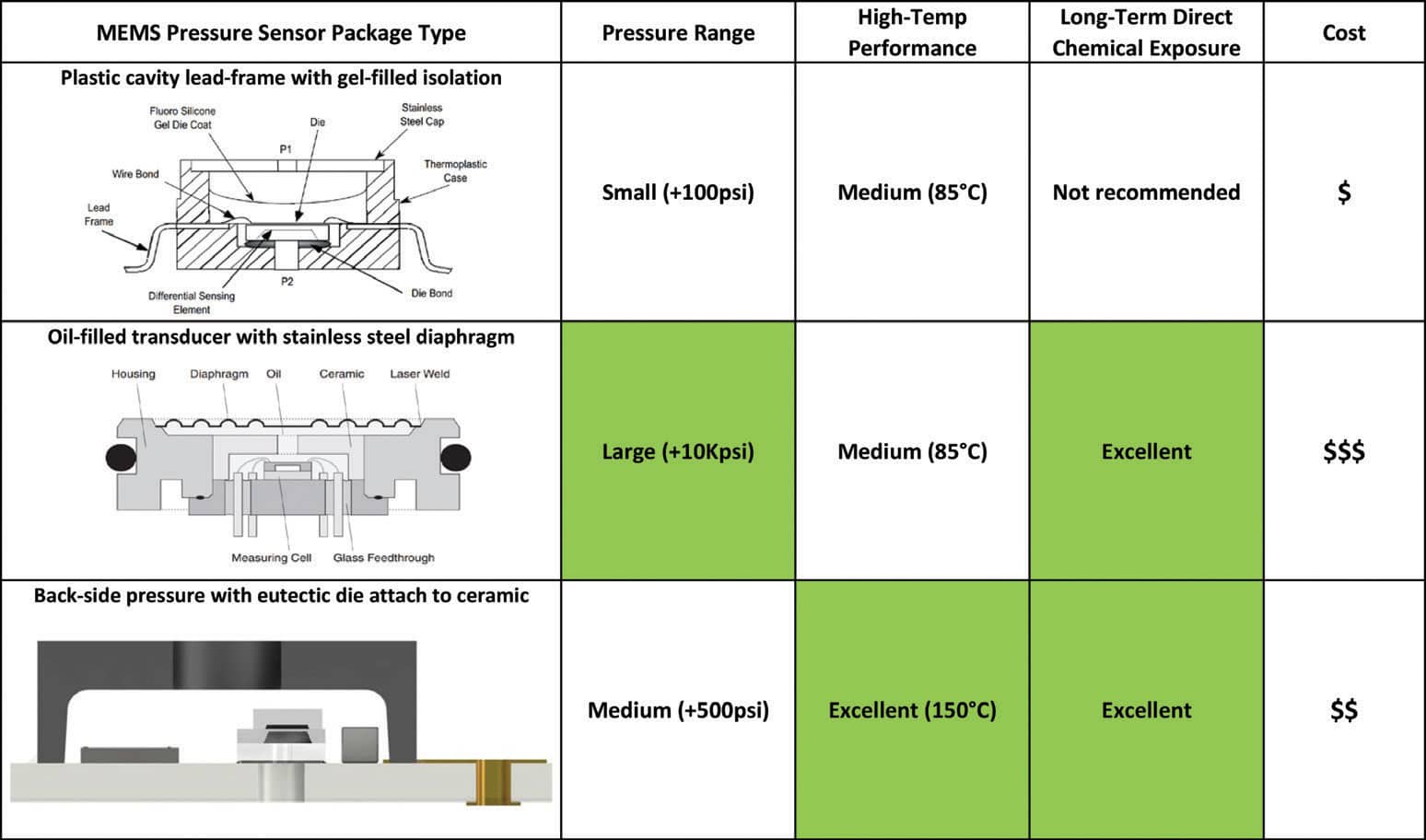

In order to perform well in the ranges between -40 °C to +150 °C, a pressure sensor requires a stable MEMS element as well as stable packaging and manufacturing processes. However, instability usually occurs due to differences in the TCE (thermal coefficients of expansion) of the MEMS die and the substrate on which it is mounted. Although, stainless steel might be considered a perfect substrate, its TCE is much higher than that of silicon. The metal expands and contracts, as temperature changes, while the silicon elements soldered onto it go through much smaller changes. The MEMS element reacts to the stresses caused by the TCE differences, inducing errors that seem like pressure changes to the system—thus giving system designers a new reliability issue.

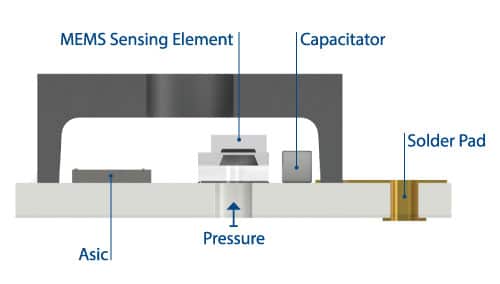

An innovative new pressure sensor packaging approach creates a eutectic die bond on ceramic substrate using a gold-tin soldering alloy for a hermetic seal even at extremely wide temperature ranges, in harsh fluids and at high pressure. The ceramic substrate features a TCE that is close to silicon so there is no considerable thermal mismatch, and tin and gold are common soldering elements that adhere well to harsh fluids.

While manufacturability is affected by their high individual melting points, an alloy with a much lower melting point is produced by a gold-tin soldering bond with an 80:20 ratio. This in turn enhances manufacturability at the same time as retaining the benefits of both metals in harsh environments. Despite the fact that this gold-tin solder is more expensive than adhesive, the cost differential is small when compared to the considerable improvement in maintenance costs and long-term reliability.

Table 1. Comparison of pressure sensor package types across harsh application requirements.

Conclusion

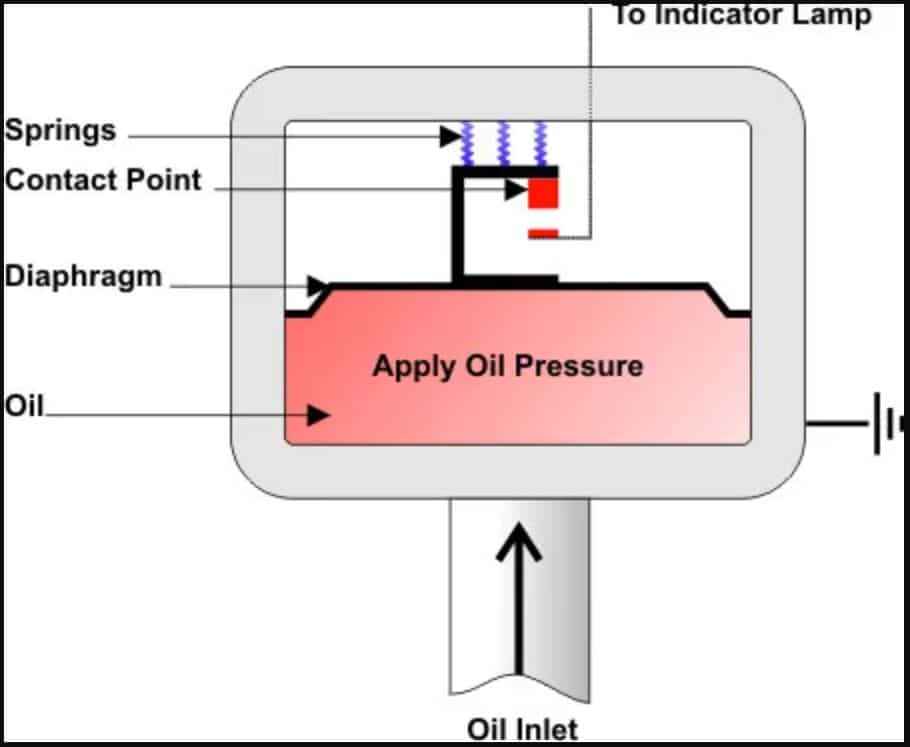

Checking whether the pressure media comes in at the back side or top of the sensor is an additional aspect to be considered while comparing sensor packaging approaches. The circuitry must be protected from corrosion or shorts if the pressure is on the top side of the sensor. This protection is usually achieved with a protective gel. However, a gel that is stiff enough to bear corrosive fluids is generally also stiff enough to cause stress to the MEMS element, which, again, produces sensing errors. On the contrary, back-side entry uncovers only the eutectic die attach, glass and silicon to the pressure medium—elements that have been proven to withstand these harsh environments.

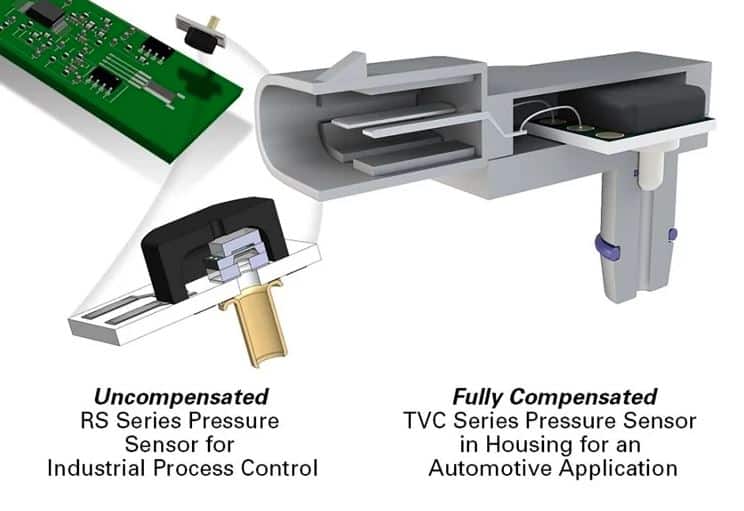

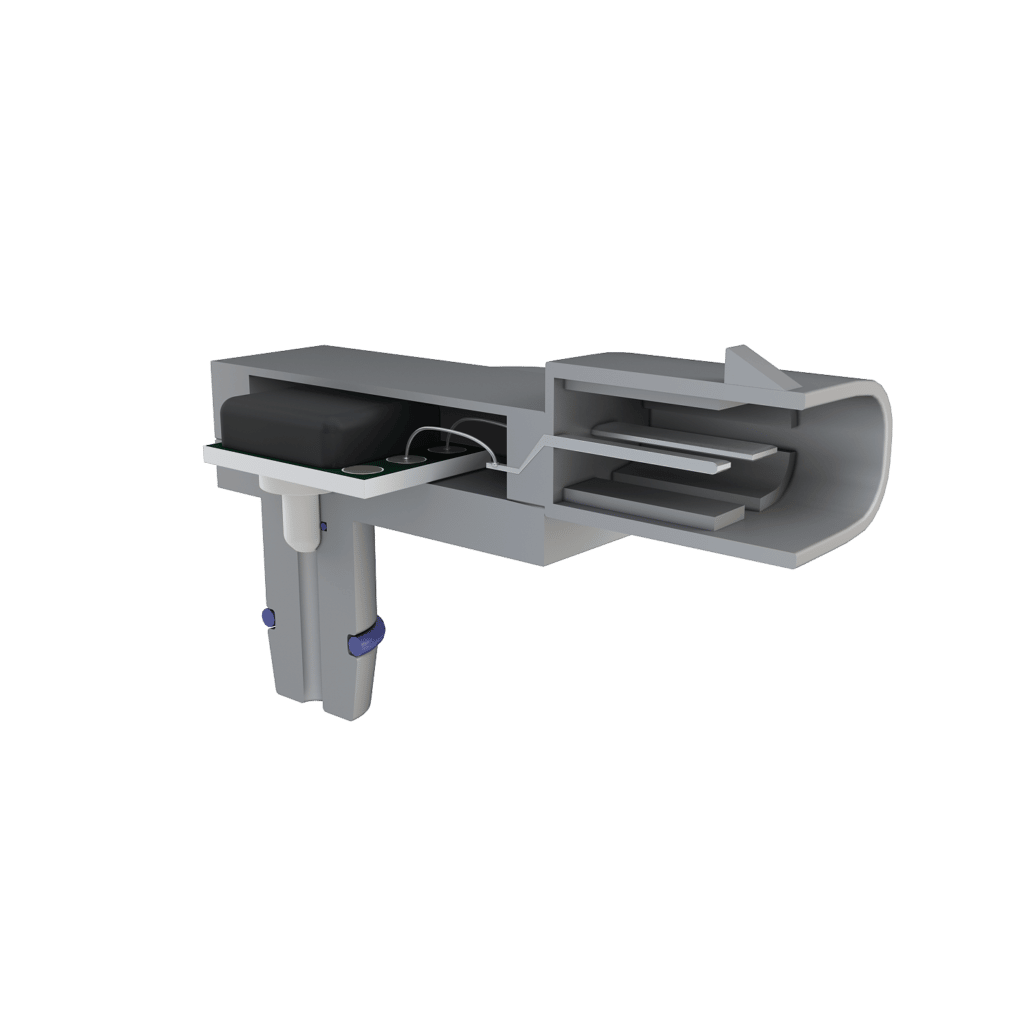

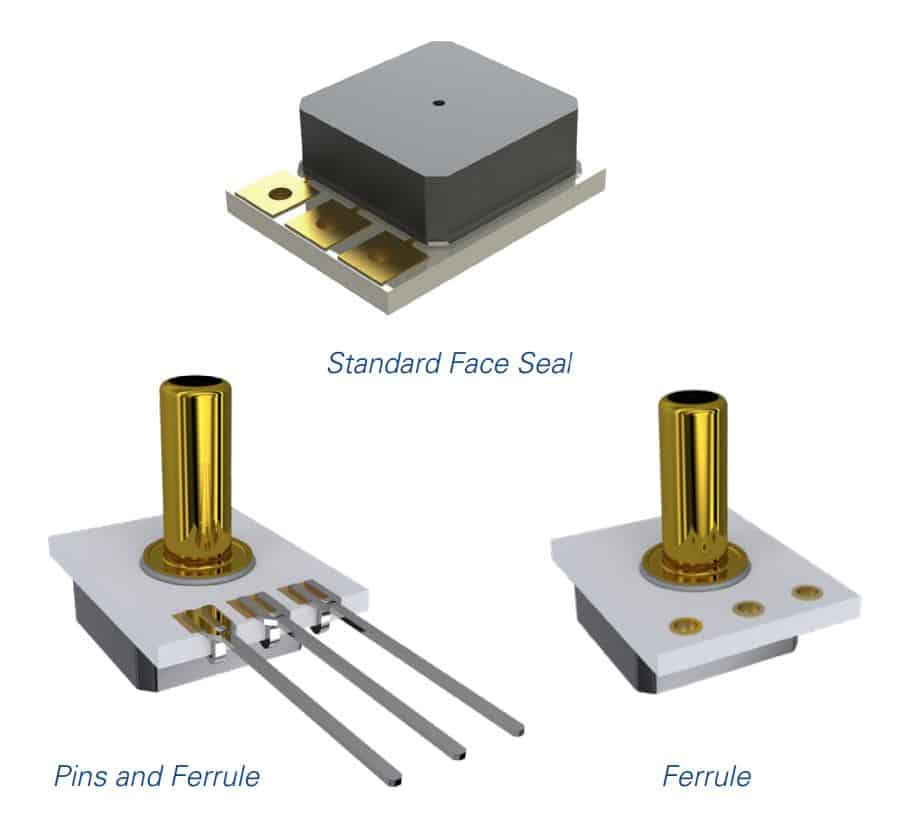

Figure 2. Merit Sensor harsh-media, extended-temperature sensors are available with optional ferrule (right), pins and ferrule (left) and standard face seal. (top).

System developers who are in need of pressure sensing abilities in extended-temperature, harsh-media applications have found that packaging is important to lower ownership cost and enhance product lifetime reliability. This challenge has been eventually resolved.

For more information, visit this article on AZOSensors.com