Pressure Sensors and Their Use in Aquatic and Underwater Applications

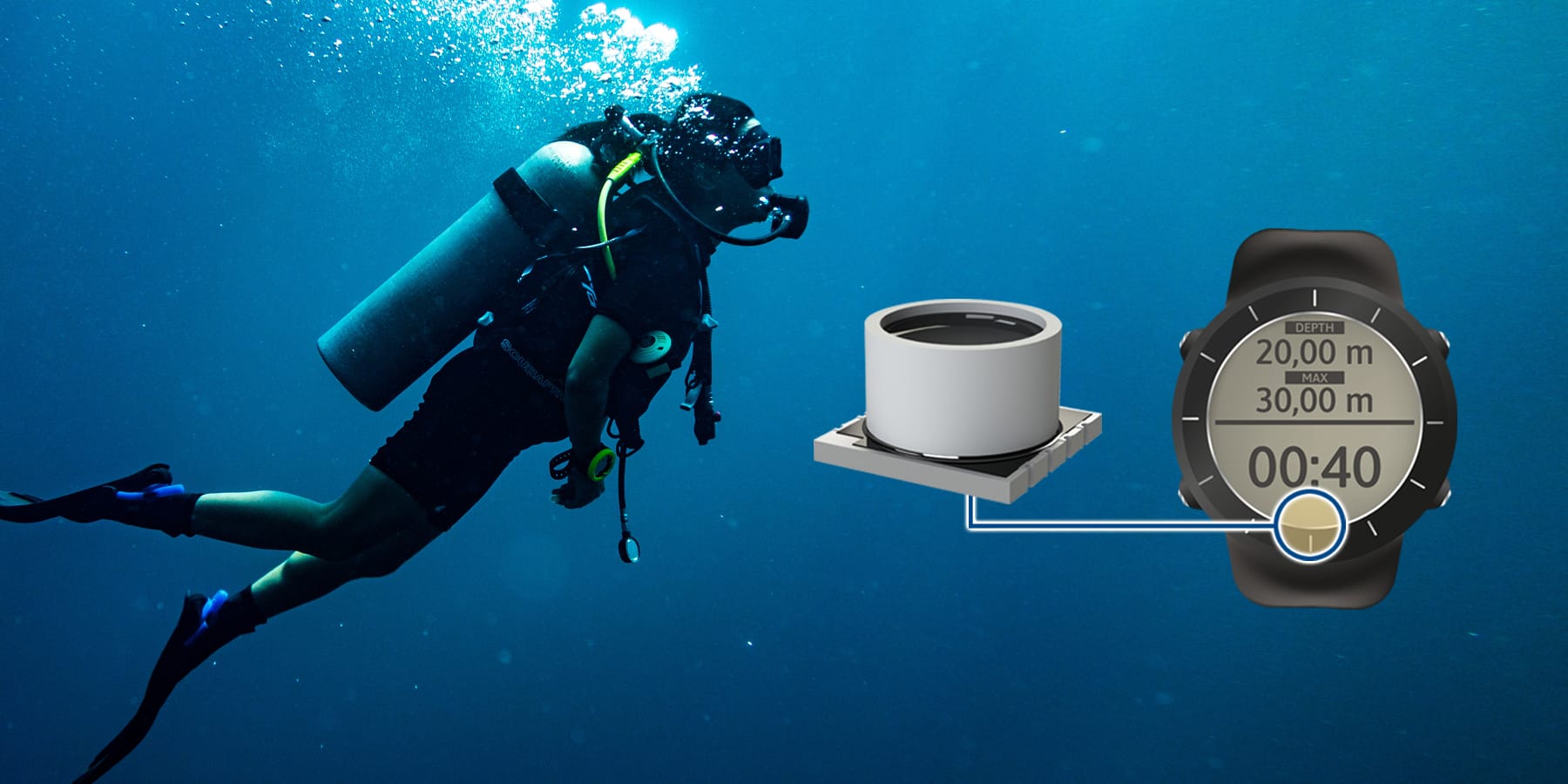

Pressure sensors are essential safety and logistic equipment in a number of underwater applications. For scuba diving, a reliable depth gauge or diving watch is crucial to estimating diving depth and ensuring safe ascent and descent.

Historically, many dive watches and depth gauges have been analog designs. Digital pressure sensors have several advantages over analog sensors and can be easily interfaced with dive computers that combine information from multiple sensors.

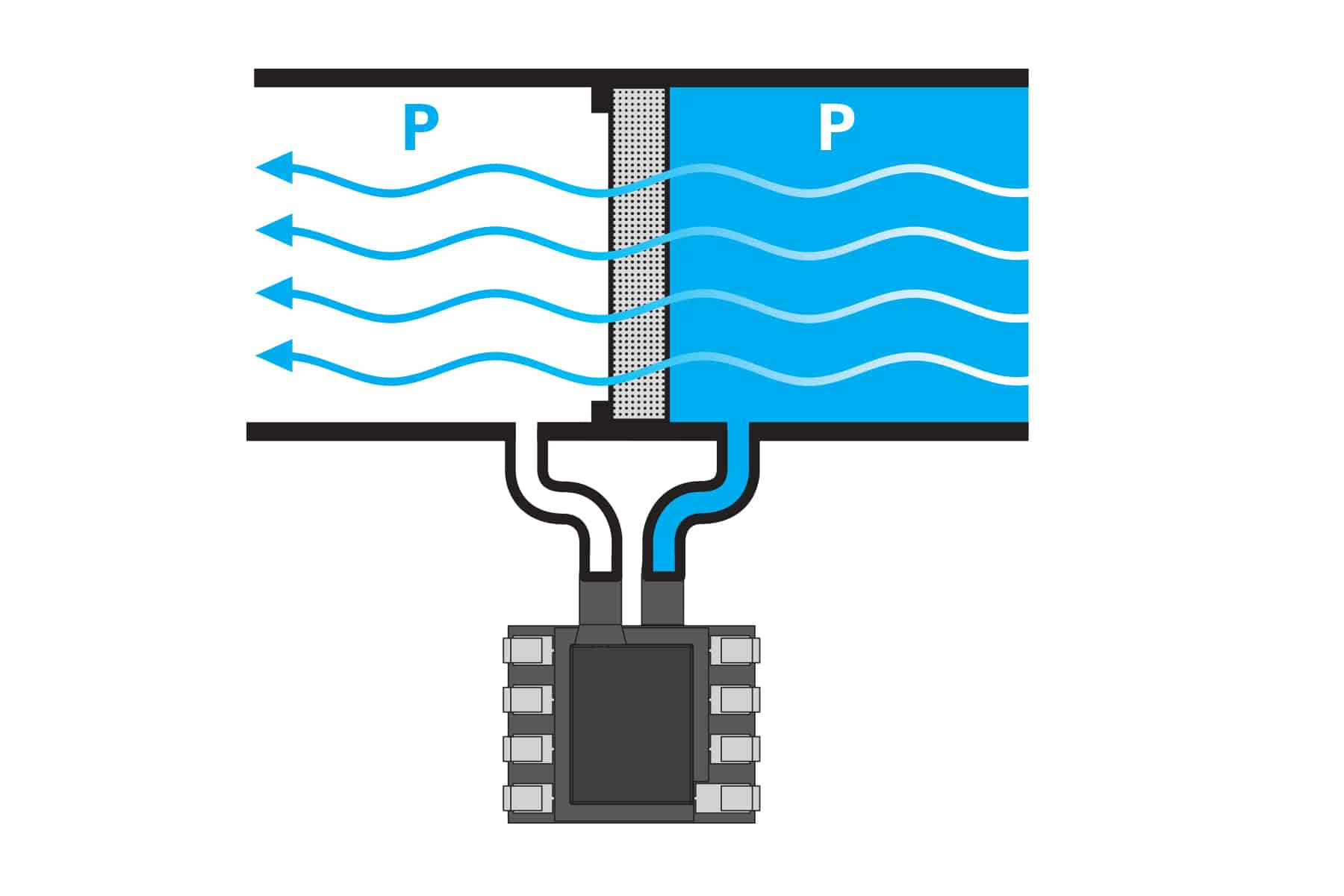

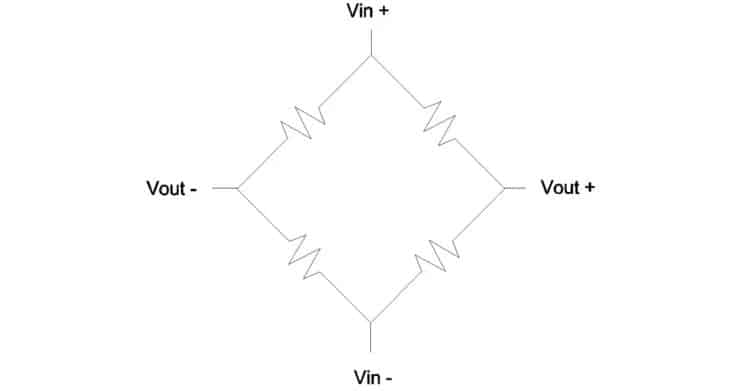

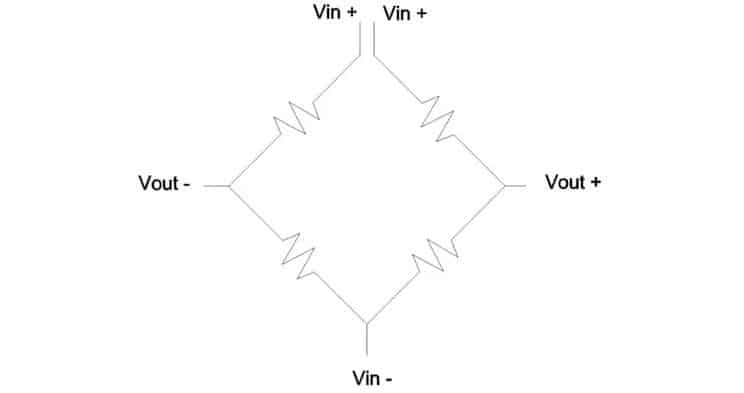

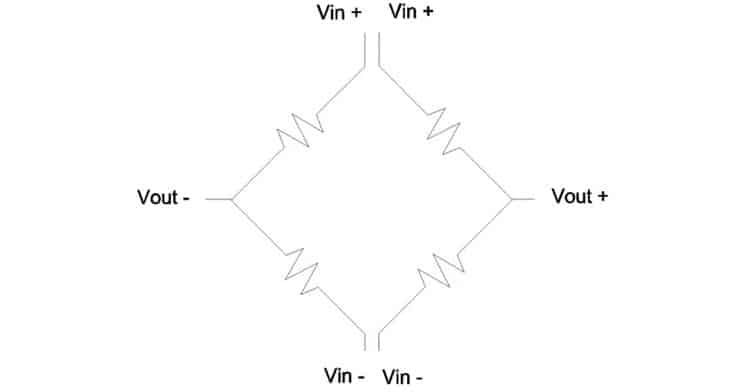

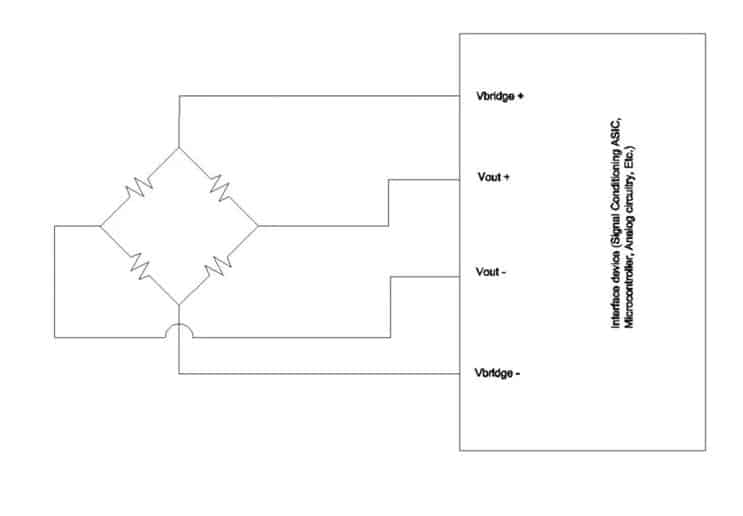

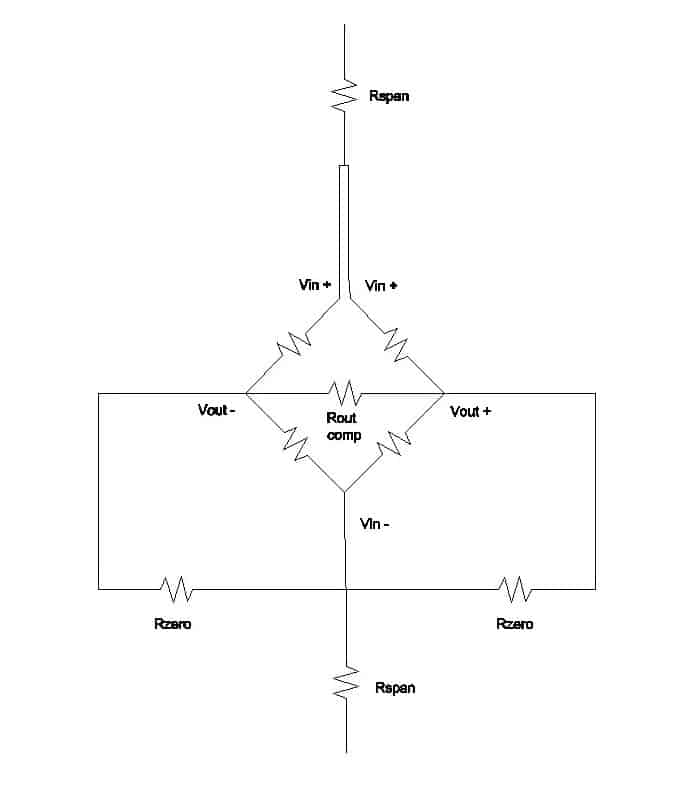

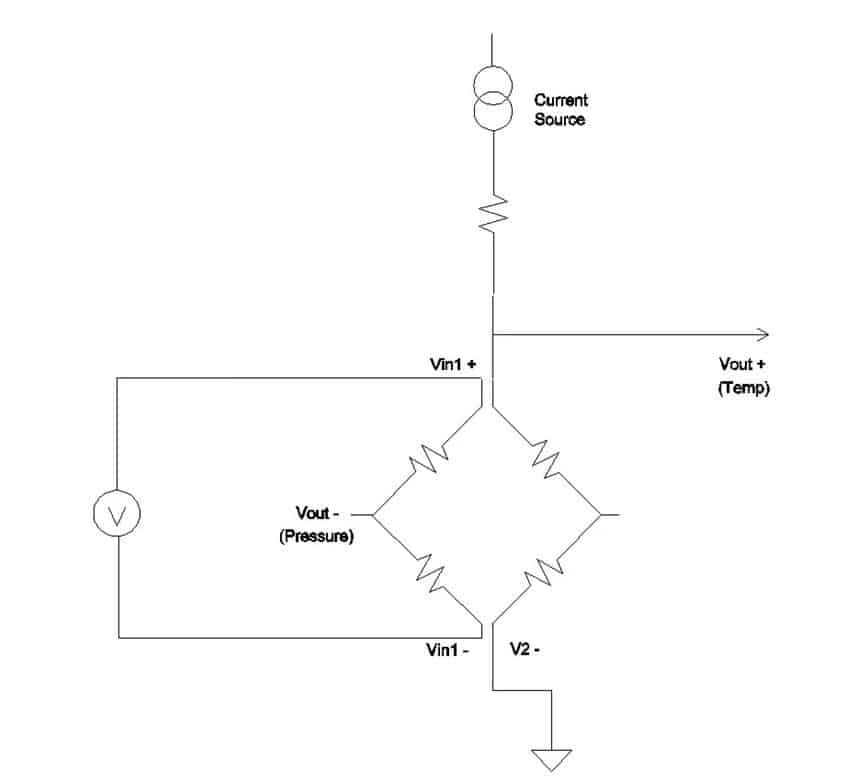

A digital pressure sensor will consist of the sensing element; for pressure sensors, this is often a piezoresistive element and a transducer to convert the sensor response into a digital signal for processing. Digital sensors can be very compact, with no moving parts and can be used in harsh and corrosive environments, including in salt waters. Piezoresistive sensors are particularly well-suited for aquatic measurements as they have few restrictions on their operating depths.1

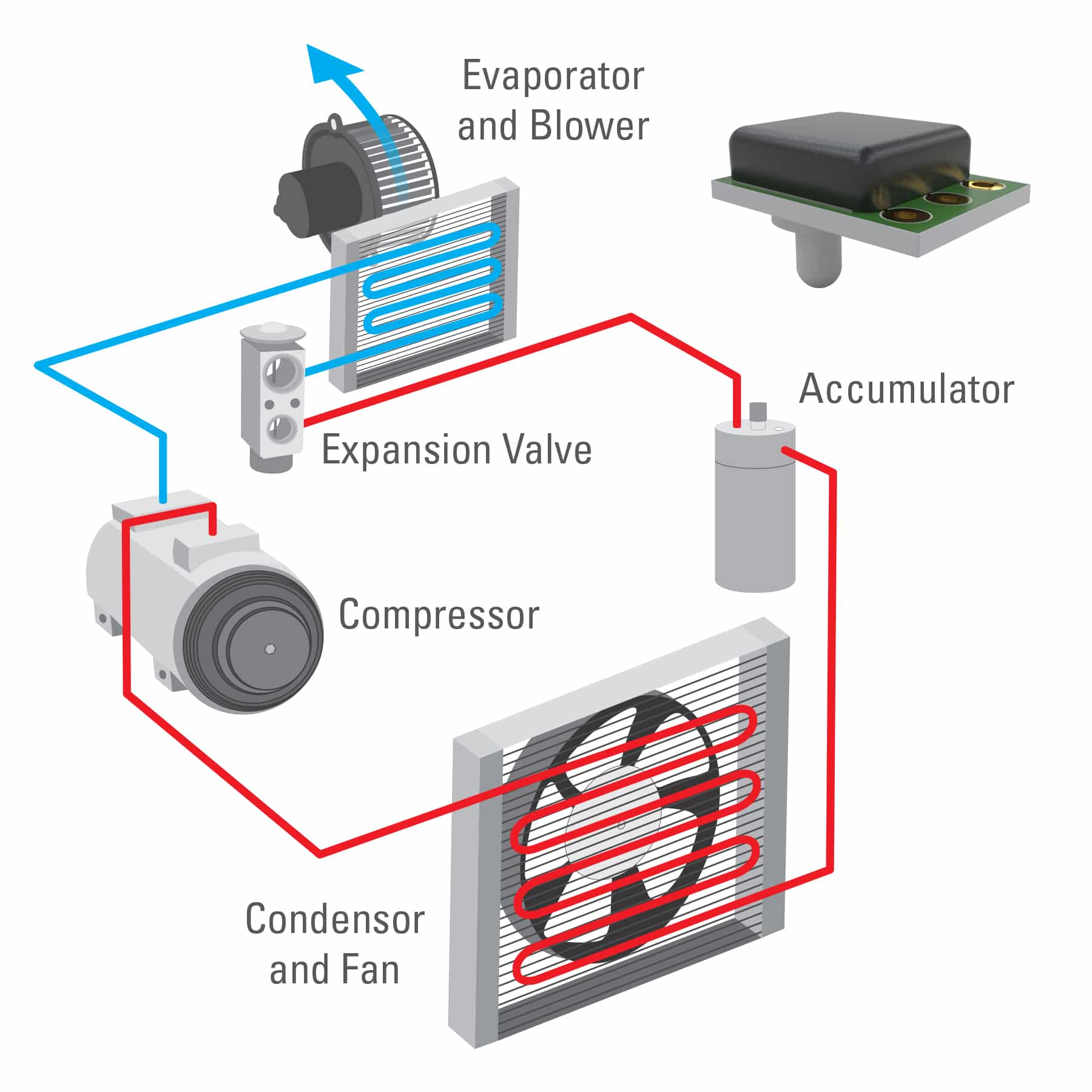

Common applications of such pressure sensors include sonar buoys, sometimes known as sonobuoys, tank and ocean depth measurements, dive watches and fishing.

Merit Sensor Systems

Merit Sensor Systems is a leading expert in pressure sensors for a number of applications, including diving and freshwater work. Merit Sensor Systems offers several different sensing devices with incredibly small footprints and ultra-low power draw. The low power consumption is essential for many remote aquatic applications as devices must be battery operated and require a battery life of many hours.

For sonar buoys, deployable devices that use sonar signals to locate passing submarines and marine traffic or monitor tidal conditions, Merit Sensor Systems has developed pressure sensors that can replace the traditional wire/line technology. Normally, a buoy would be deployed with a spool of wire connecting the device to a float at the surface and the length of the wire is used to estimate the depth of the device. However, as the ocean is constantly moving, the wire displacement is often a bad measure of the depth due to lateral deflections of the device while it is in the water. A pressure sensor can instead provide more accurate depth measurements by measuring the local water pressure.

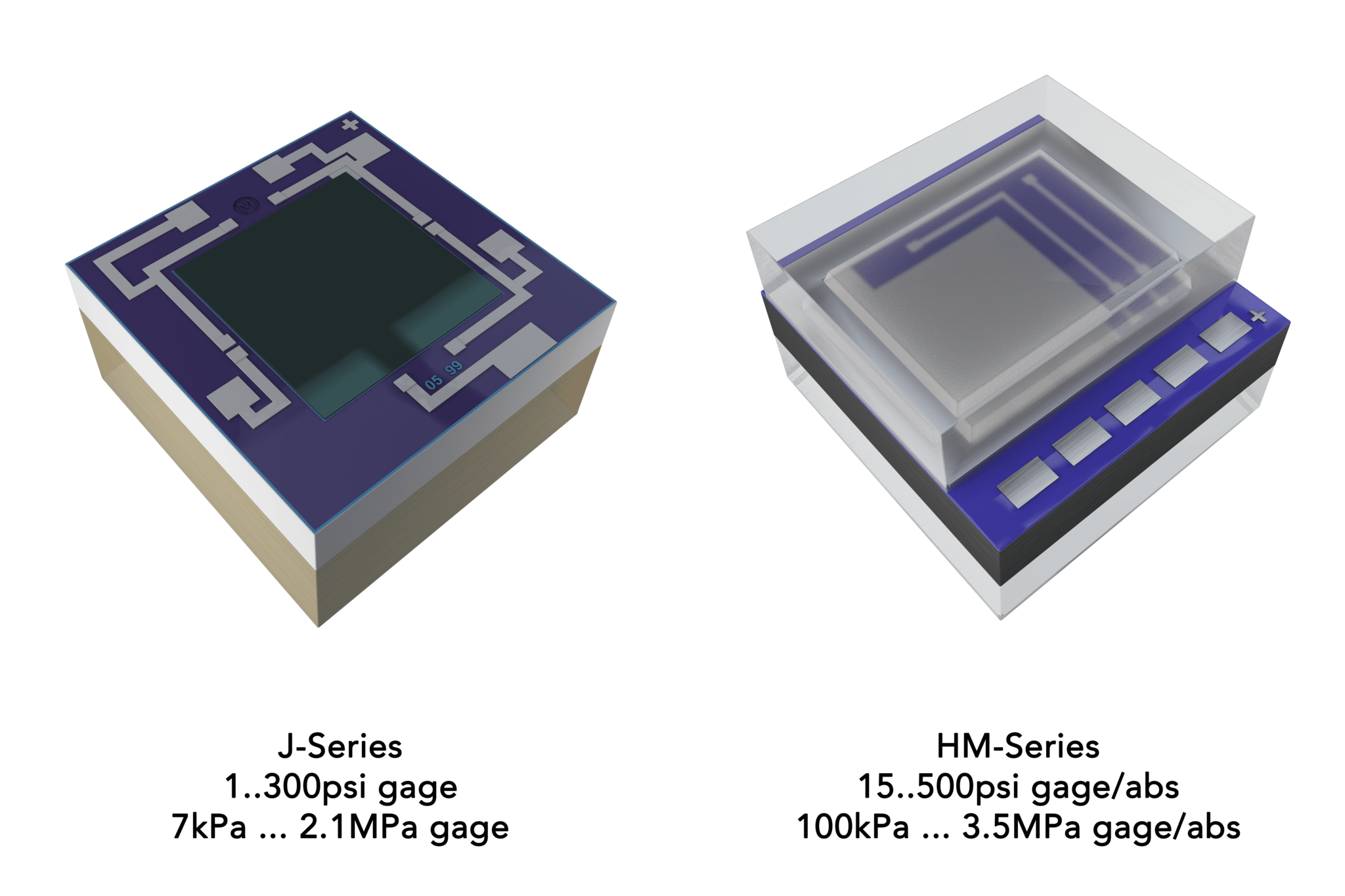

For sonar buoys, Merit Sensor Systems offers a range of suitable sensors, including the HTS 1510 Series, the TR series and, for more limited operating depths, the ultra low power MS series. All of these are highly compact, lightweight sensors that can be easily incorporated into a range of devices and provide many hours of continuous operation. The HTS series will also soon feature a Sleep mode so that the battery life can be further preserved.

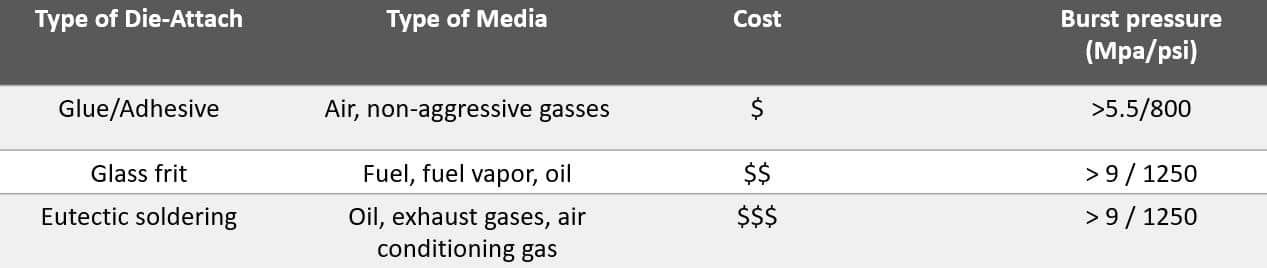

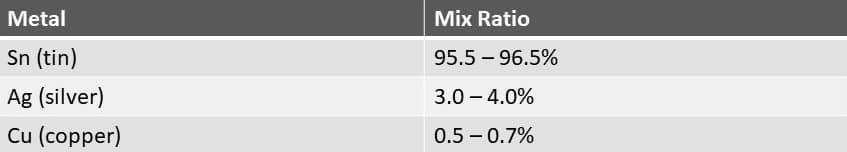

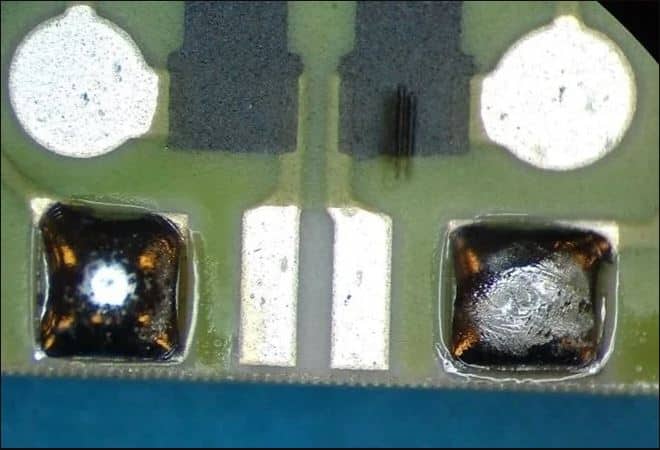

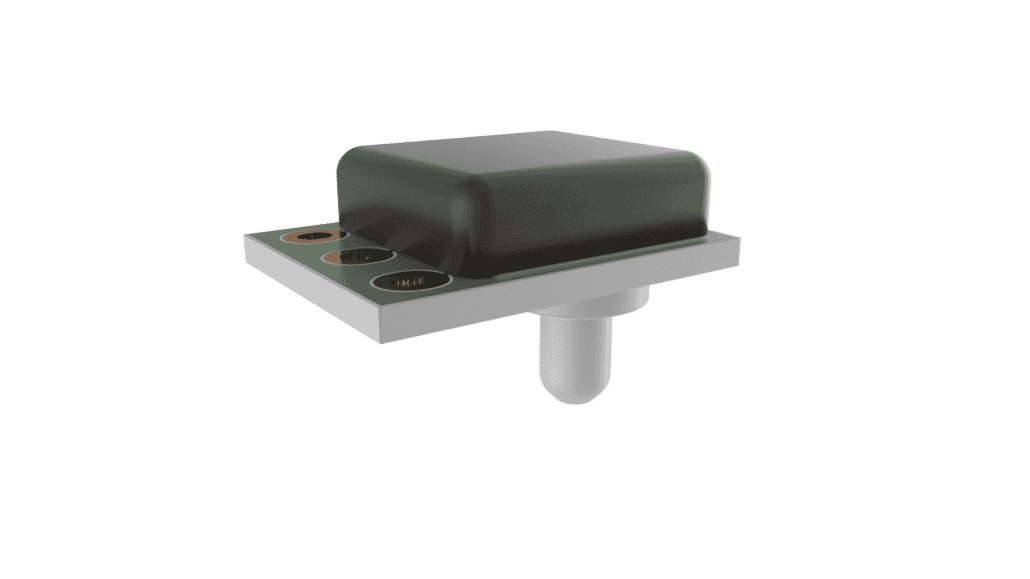

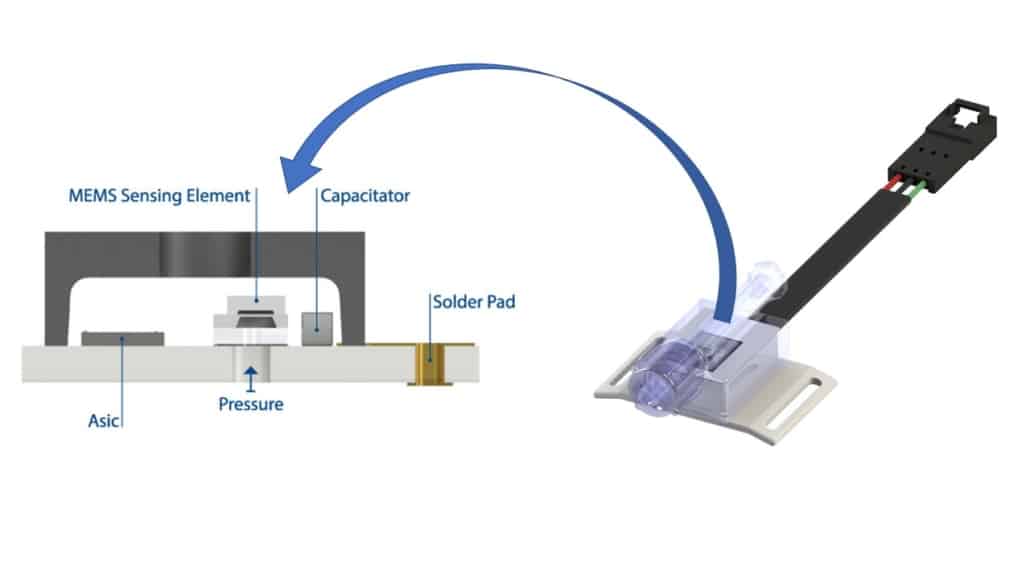

All of the Merit Sensor Systems series are extremely media compatible with a range of water environments and conditions. The MS series is gel-filled for additional protection and its compact design footprint means it has been successfully used in dive watches. The MS series is an affordable option with excellent stability over an extensive temperature range and is also RoHS compliant.

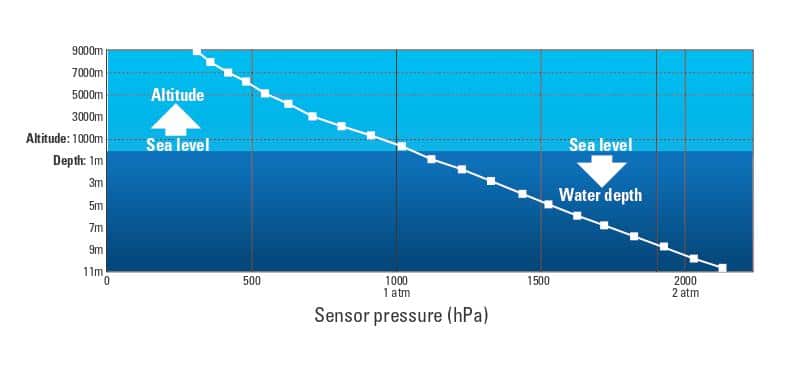

Calculating Depth

Why do pressure sensors work so well for recovering depth information? As the density of water is constant in most environments, as is gravity, the underwater pressure is directly proportional to the submersion depth. With onboard electronics for the processing, a pressure sensor can rapidly convert these pressure readings into a measurement of submersion depth or even the local water level.

Diving computers can display and process a range of pressure information, from remaining gas levels in breathing tanks to diving depth. Some dive computers will use this to calculate the remaining safe time for a dive.

All of the Merit Sensor Systems pressure sensor series can be integrated as part of digital systems, but the HTS 1510 Series has the choice of providing digital or analog outputs.

Important for live depth calculations, all of the pressure sensors have 10 ms start up times in case devices need to be rebooted rapidly. Each pressure sensor is less than 2 g in mass, including any protective housing and mounts required, particularly for saltwater applications.

These pressure sensors are characterized by their potential to perform high accuracy measurements with only 0.5 % FS lifetime drifts, incredibly low pressure and temperature hysteresis. Whether you need a pressure sensor that can uphold the highest safety standards for manual diving, or a quick readout sensor for 24/7 online water tank monitoring, Merit Sensor Systems has something to offer.

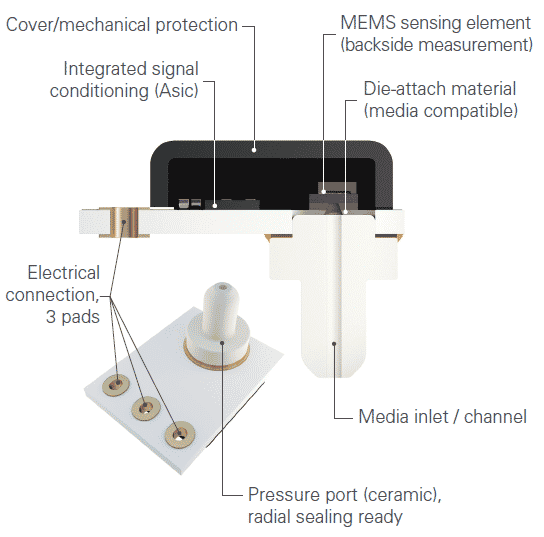

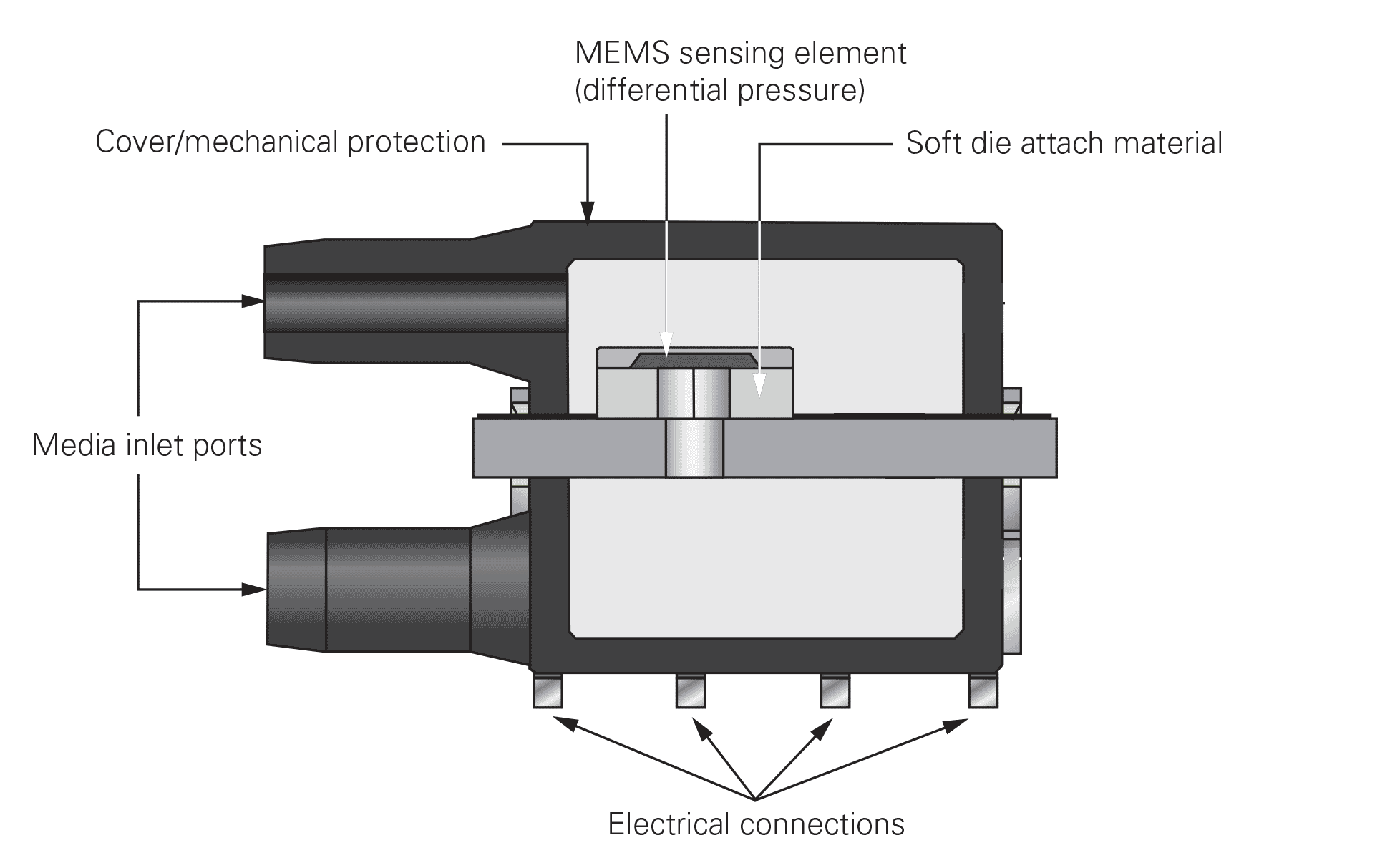

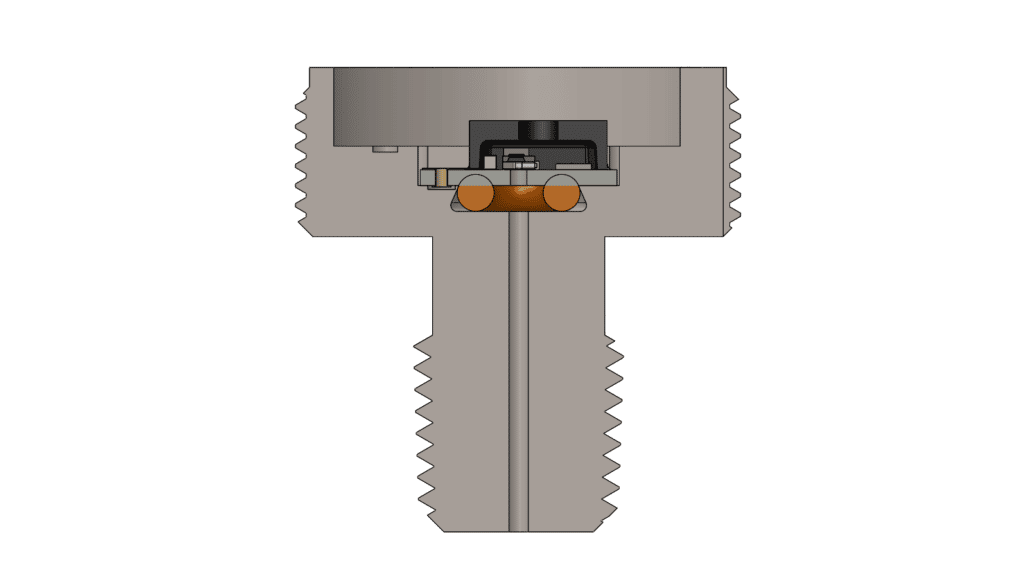

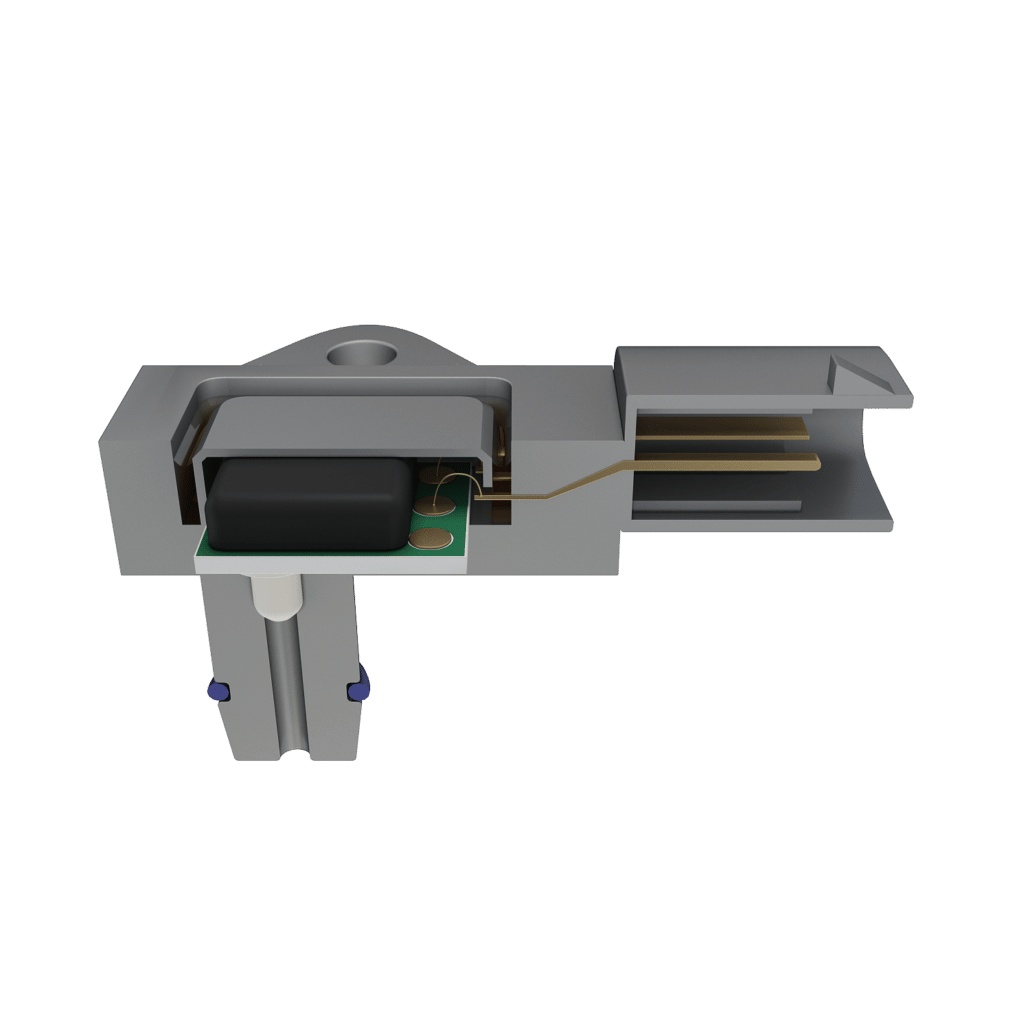

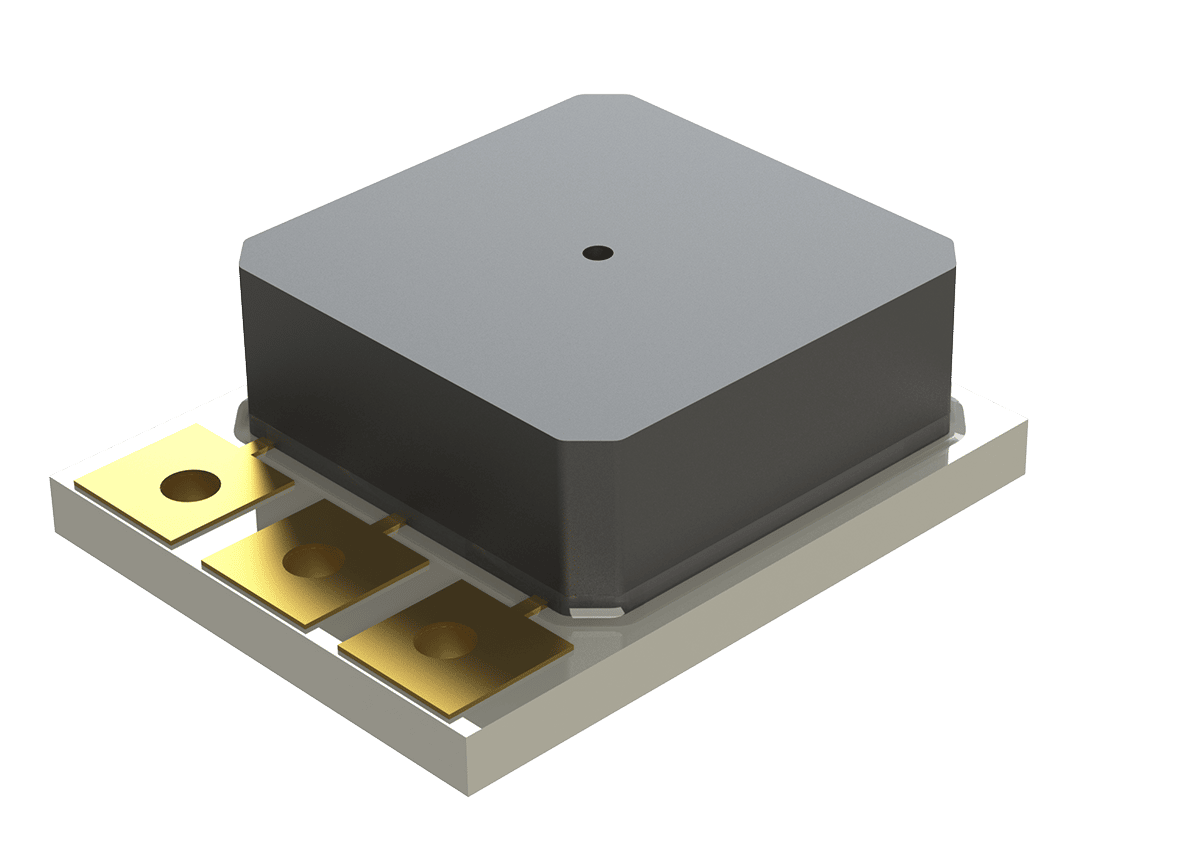

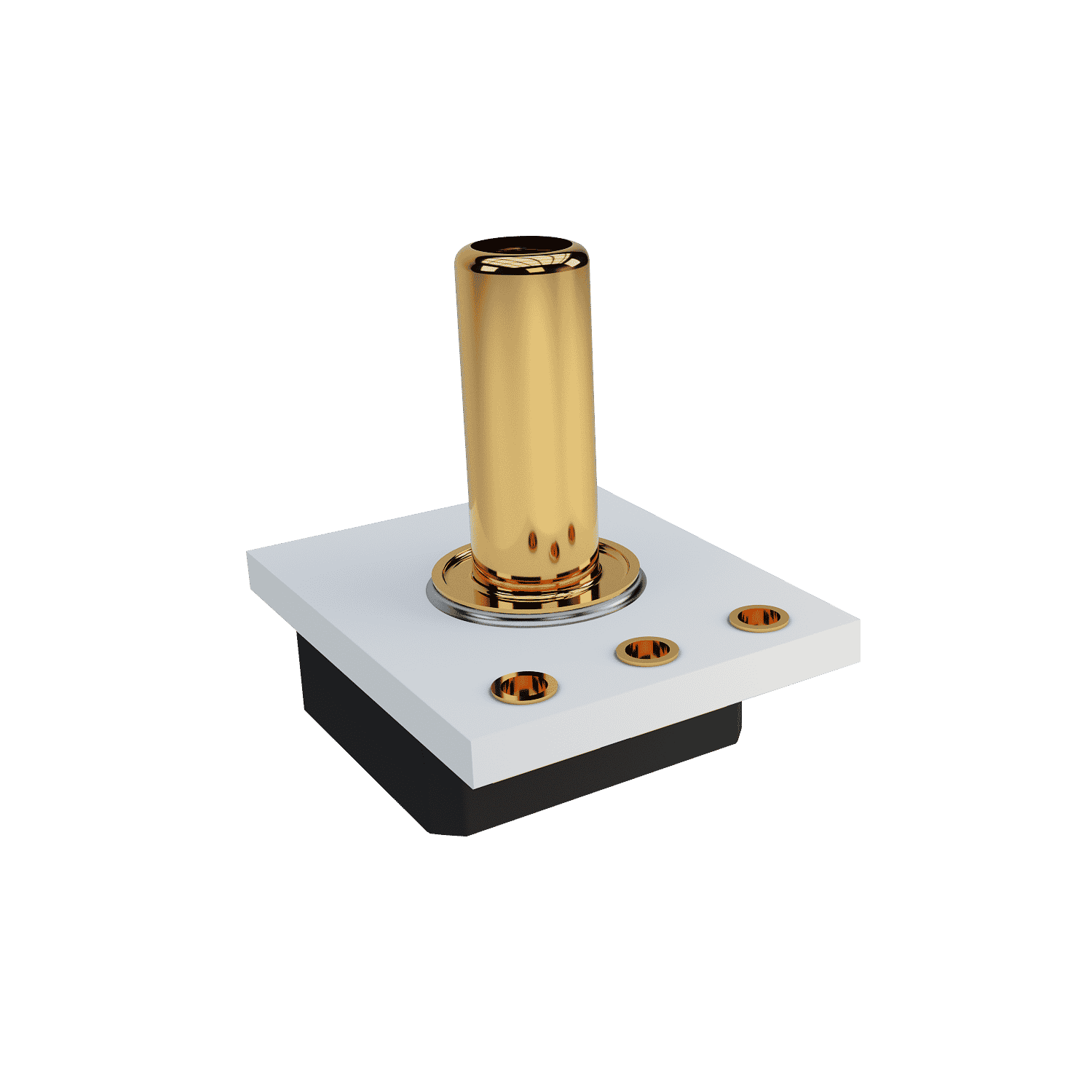

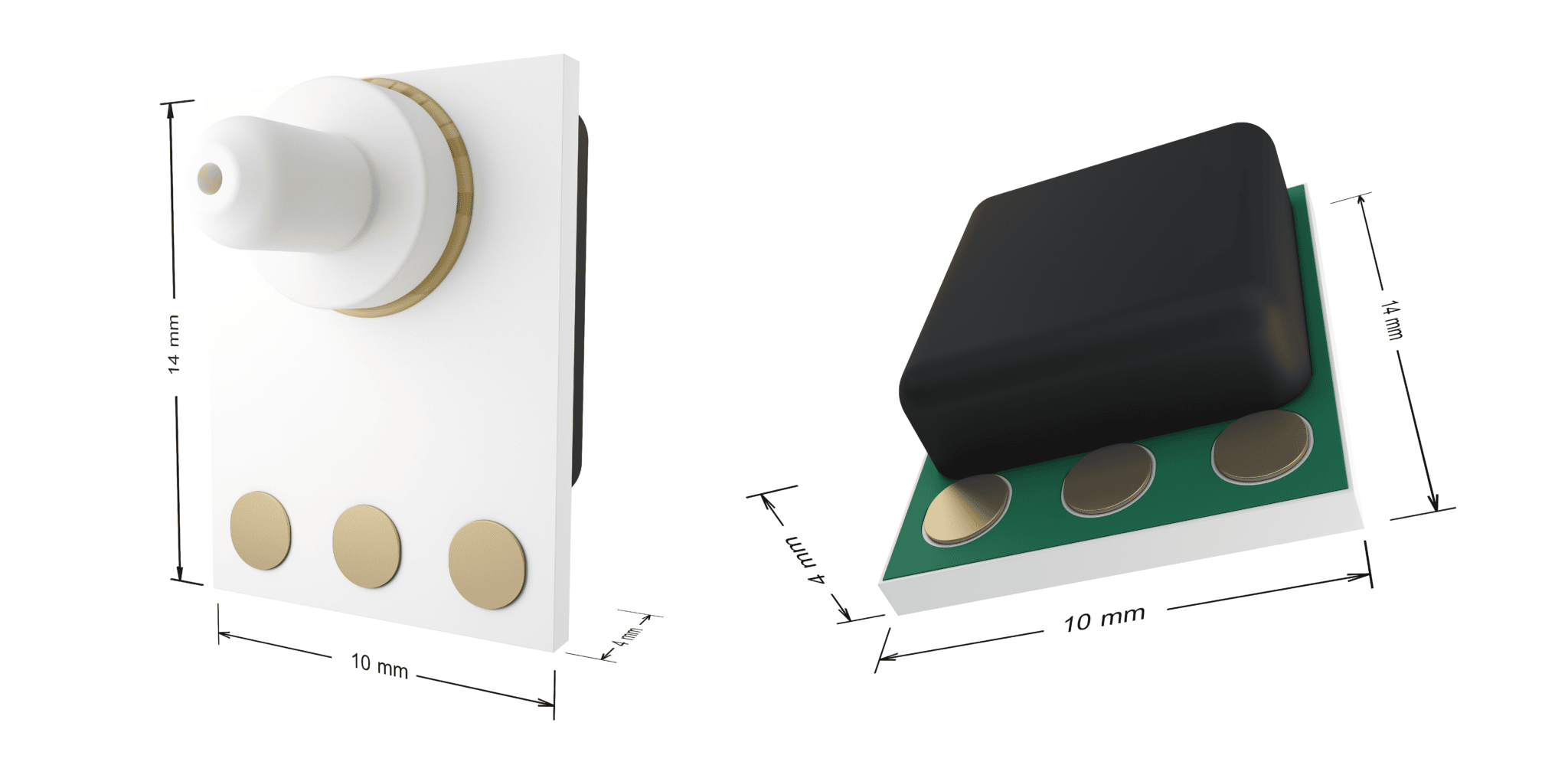

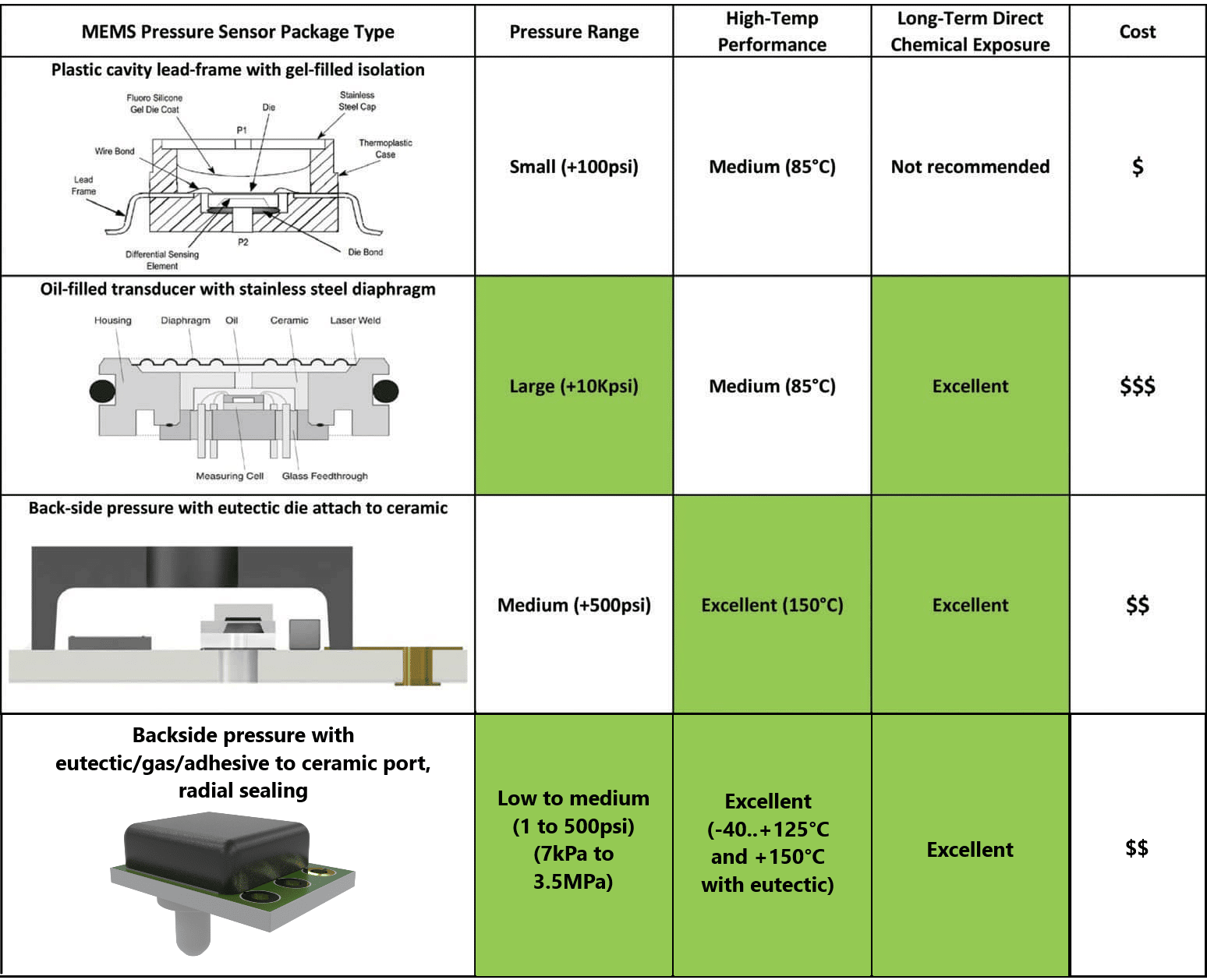

The HTS 1510 Series, the TR series and the MS series each have different designs and housing to optimize them for particular tasks. The MS series is a surface-mounted, ceramic device. The fully-compensated TR series is a direct-media pressure monitor, designed to plug and play with existing devices. The HTS1510 series is a backside-pressure monitor which can be surface-mounted and integrated into existing control boards.

Contact Merit Sensor Systems today to find out how their state-of-the-art pressure sensors could be integrated into your underwater devices.

References:

- Büttgenbach, S., Constantinou, I., Dietzel, A., & Leester-Schädel, M. (2020). Case Studies in Micromechatronics. In Case Studies in Micromechatronics. https://doi.org/10.1007/978-3-662-61320-7

For more information visit this article featured on AZOSensors.com